變壓器真空乾燥爐

TRANSFORMER VACUUM FURNACE US-6S 型號:US-6S-

我們向您介紹一種變壓器真空乾燥爐US-6S,是為乾燥電力變壓器的固體絕緣而設計的。

在電力變壓器的生產或維修過程中,一個常見的做法是去除絕緣紙層的水份。由於水份會影響其耐壓能力,所以乾燥後的絕緣層的介電強度比未乾燥的絕緣層大20倍。

根據變壓器的類型,有幾種方法可以去除活性部分的水份。其中之一是用真空爐(真空烤箱)乾燥。

使用真空爐對電力變壓器進行乾燥,有以下優點:

- 與熱風乾燥或自然乾燥相比,使其水份的蒸發更加確實。

- 有效提升整體性能和減少處理時間。

GlobeCore提供經過精心設計的變壓器真空爐,以滿足客戶的具體需求。該設計,考慮到了生產力、尺寸和放置位置、裝載方法、自動化程度等。

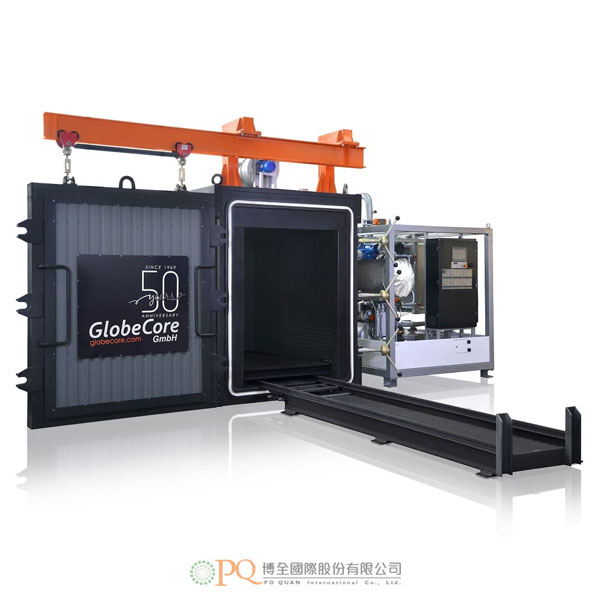

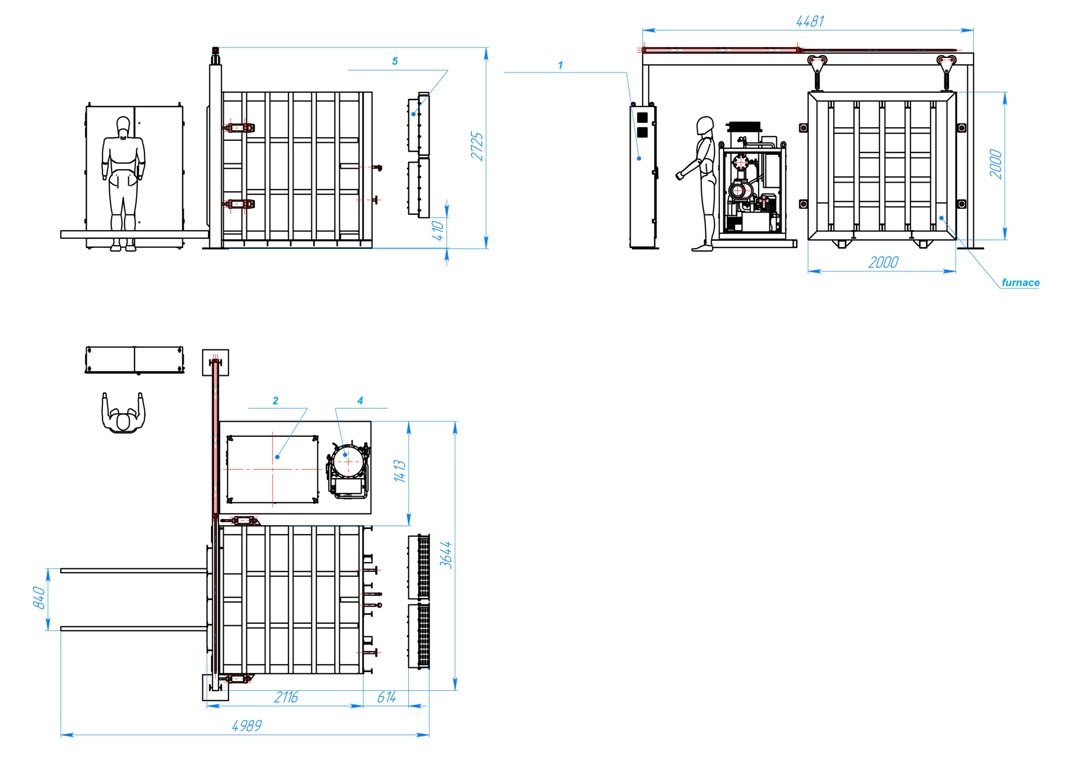

下圖是一個變壓器真空爐US-6S 的主體和組件:

- 控制機櫃

- 真空裝置BV-1000

- 壓縮機

- 油的加熱器PPM-18

- 蒸汽冷凝器

- 冷凝液收集槽

- 爐室

- 爐室的入口門

- 滑動軌

操作原理

變壓器的放置可由移動式起重機或裝載機裝載到滑動軌上。滑動軌的移動(電門驅動)、爐室入口門的關閉和打開(氣動驅動)……等控制由操作者從控制機櫃中進行。

爐室的加熱是由技術油完成的,而技術油的產生是透由,如GlobeCore的線上油加熱裝置(PPM-18 / PPM-50 /PPM-70)帶到所需的溫度。

請記住,變壓器真空爐的價格取決於所需的尺寸、體積和客戶的工藝技術特點。

附加功能

此外,GlobeCore還生產用於各種原材料的真空乾燥箱:

- 粉末和膏狀物。

- 加工食品。

- 原生木材……等等。

優勢

- 使整個變壓器鐵心體積均勻乾燥。

- 經濟地使用電力功率。

- 縮短乾燥時間。

- 操作簡單。

- 有效排除變壓器內的水份。

-

We present to your attention a transformer vacuum furnace US-6S, designed for drying the solid insulation of power transformers.

A common practice during the production or repair of power transformers is to remove moisture from paper insulation. The dried insulation has dielectric strength4 20 times greater than not dried one, as moisture affects its dielectric breakdown.

Depending on the types of transformers there are several ways to remove moisture from the active part. One of them is drying with a vacuum furnace (vacuum oven).

Drying of power transformers with a vacuum furnaces has the following advantages:

- more intensive evaporation of moisture in comparison with drying with warm air or natural drying;

- optimal overall performance and reduced processing time.

GlobeCore offers a transformer vacuum furnace with modifications, adapted to meet specific needs of the customer. The design, accounts for productivity, dimensions, and placement location, loading method, degree of automation, etc.

The following picture shows a vacuum drying cabinet US-6S.

Transformer vacuum furnace: the main components and assemblies

- Control cabinet

- Vacuum unit BV-1000

- Compressor

- Oil heater PPM-18

- Vapor condenser

- Condensate collection tank

- Furnace chamber

- Door of the furnace chamber

- Sliding carriage

Principle of operation

The active part of the transformer is loaded onto the sliding carriage by a travelling crane or a loader. The control of the carriage movement (motorized drive), closing and opening of the doors of the furnace chamber (pneumatic drive) is performed by an operator from the control cabinet.

To heating of the furnace chamber is done by technical oil, which, in turn, is brought to the required temperature by an oil flow through heater.

Remember that the price for a transformer vacuum furnace depends on the required dimensions, capacity, and technological features of the customer’s process.

Additional Features

Also, GlobeCore produces vacuum drying chambers for various raw materials:

- powders and pastes;

- food products;

- wood, etc.

Advantages

- uniform drying of the entire transformer core volume;

- economic use of electricity;

- reduced duration of drying;

- simple operation;

- removal of moisture from chamber.