STOJAN鋼絞線燃燒器

STOJAN STRAND BURNER 型號:SSB

SSB (STOJAN鋼絞線燃燒器)是Stojan高壓釜試驗儀® SV-2 儀器的改良型,用於測定固態火箭推進劑的燃燒速率。

SSB 允許 使用兩種不同的測試程序進行實驗:恒定體積或準恒定壓力。

SSB 允許 使用兩種不同的測試程序進行實驗:恒定體積或準恒定壓力。

-

SSB™ (STOJAN鋼絞線燃燒器)是Stojan高壓釜試驗儀® SV-2 儀器的改良型,用於測定固態火箭推進劑的燃燒速率。

SSB 允許 使用兩種不同的測試程序進行實驗:恒定體積或準恒定壓力。

應用SSB 用於研發、製造品質控製或雙基推進劑和複合固體火箭推進劑的在役監測。此方法可以高靈敏度和高可靠性地揭示影響受測推進劑彈道行為的以下因素:- 不同添加劑(如 : 催化劑,減速劑,粘合劑,氧化劑等)對燃速的影響。

- 預測燃燒的不穩定性或爆炸危險。

- 燃速與推進劑初始溫度的相關性。

優勢和特點

2合1裝置:

- Stojan高壓釜試驗儀SV-2 + 鋼絞線燃燒器

(克勞福德容器)。 - 工作壓力最高可達 300 bar(SB)或

500 bar(SV)。 - 透過燃燒固體推進劑進行 750 bar 耐壓測試。

- 操作快速安全,完全遠端控制。

- 不銹鋼的高壓釜形式設計,

便於清潔複合固體推進劑殘留物。 - 配備內建冷凝器的緊湊型移動式台車。

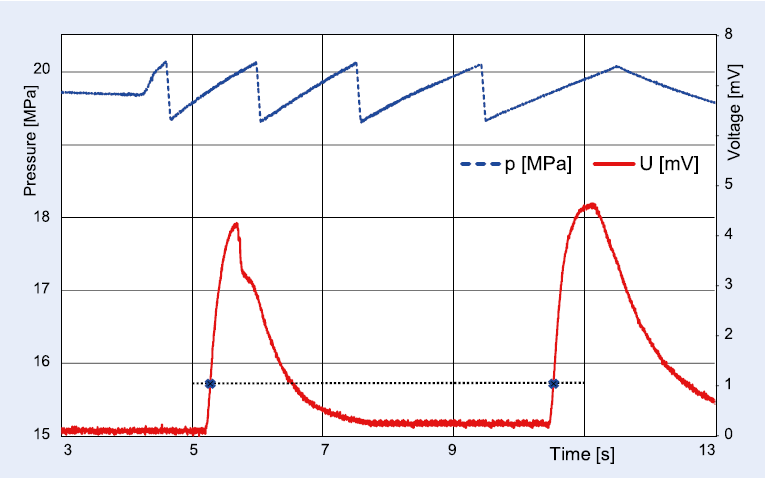

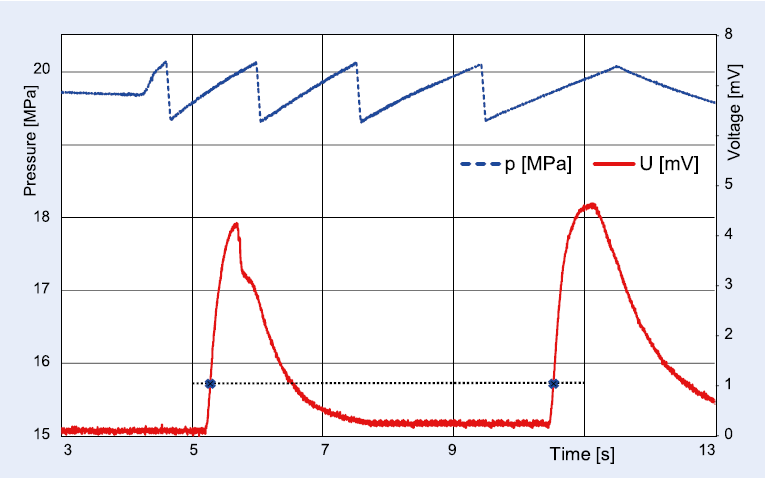

鋼絞線燃燒器模式下的壓力振盪(圖上)和

熱電偶電壓訊號(圖下)範例

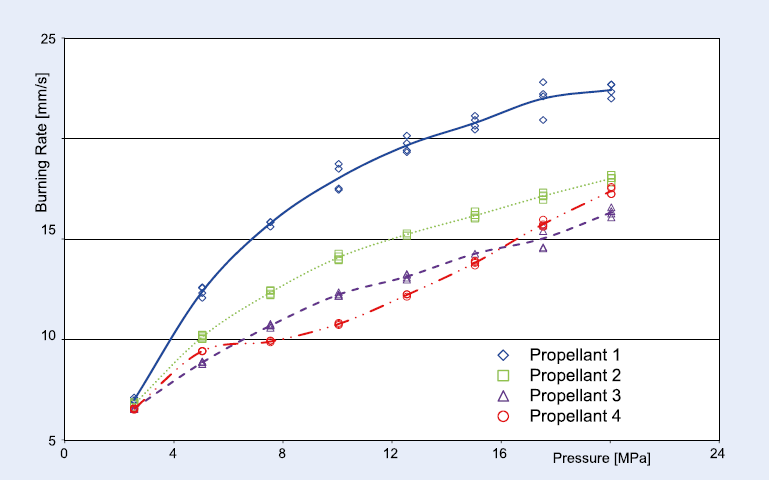

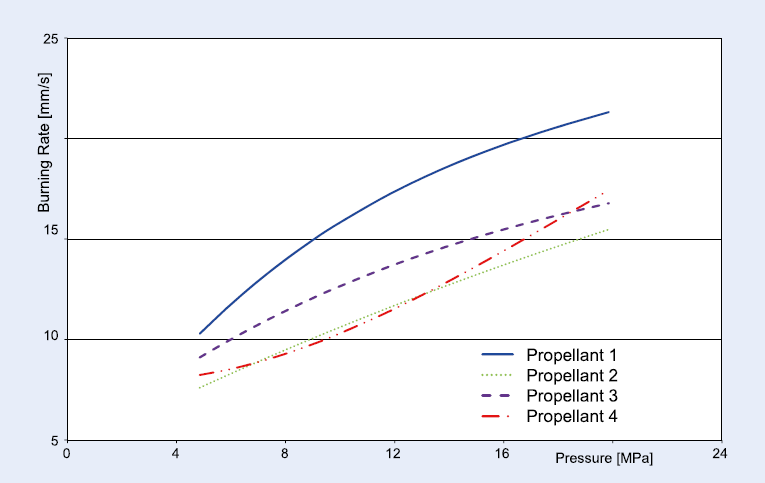

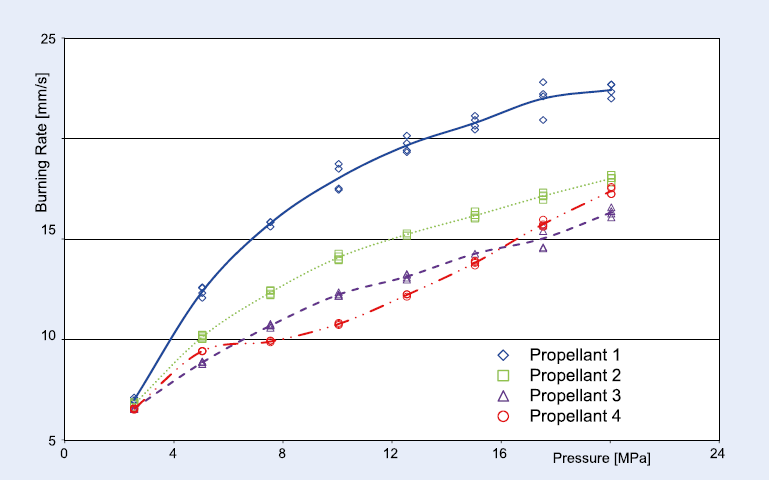

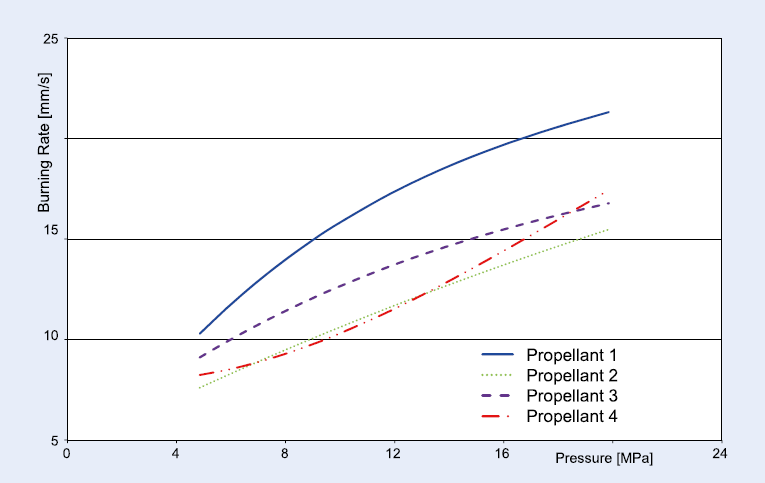

使用鋼絞線燃燒器模式測量的燃燒速率範例 使用 SV-2 模式測量的燃燒速率範例 合規

MILD-STD 286C -

The SSB™ (Stojan Strand Burner) is an improved version of Stojan Vessel® SV-2 apparatus for the determination of the burning rate of solid rocket propellants. SSB allows to conduct experiments using two different testing procedures: in constant volume or at quasi-constant pressure.

APPLICATIONSThe SSB is used for research and development, for manufacturing quality control or in-service surveillance of both double-base and composite solid rocket propellants. The method can reveal with high sensitivity and reliability the following factors influencing ballistic behavior of the tested propellants:- Influence of additives (moderators, catalysts, binders, oxidizers etc.)

- Prediction of unstable burning or explosion hazards after ageing tests

- Dependence on initial temperature

ADVANTAGES & FEATURES- 2 in1 instrument: Stojan Vessel SV-2 + Strand

Burner (Crawford bomb) - Working pressure up to 300 bar (SB) or

500 bar (SV) - 750 bar proof pressure tested by burning

solid propellants - Quick and safe operation, fully remotely

controlled - Design of the stainless steel vessel allows for

easy cleaning of the solid residues - Compact mobile working trolley with in-built chiller

Example of pressure oscillations (upper) and voltage

signal from thermocouples (bottom) for Strand

Burner mode

Example of burning rates measured using

Strand Burner modeExample of burning rates measured using

SV-2 modeCOMPLIANCE

MILD-STD 286C