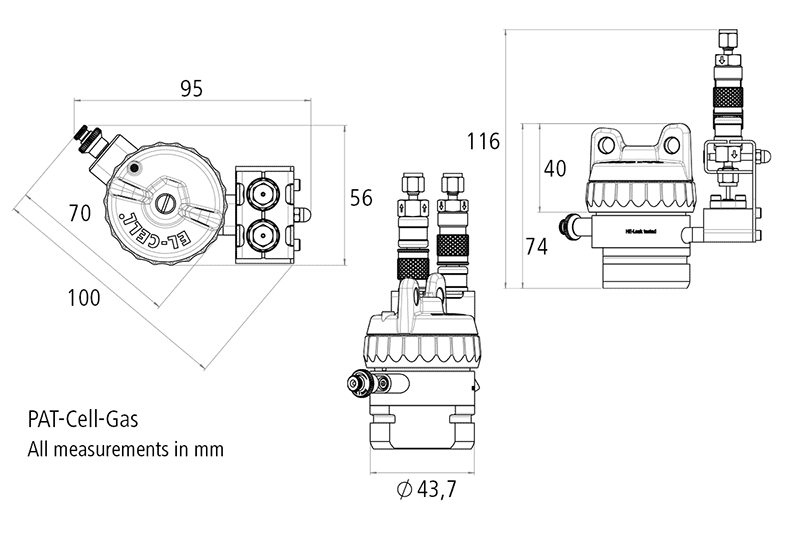

PAT-Cell-Gas

PAT-Cell-Gas 型號:PAT-Cell-GasPAT-Cell for in-situ gas analysis in a flow-through set-up

- PAT series test cell with gas inlet and outlet

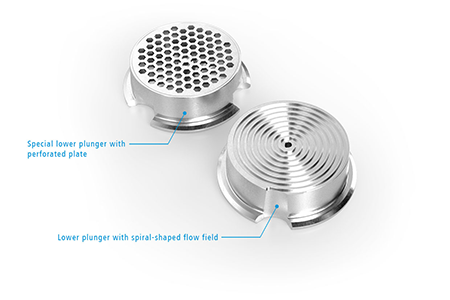

- Lower plungers with perforated plate and with spiral-shaped flow field for optimized plug-flow available.

- Optional laser-welded pressure sensor, 0 to 3 bar abs.

-

PAT-Cell for in-situ gas analysis in a flow-through set-up

Our versatile test cell for in-situ gas analysis

The PAT-Cell-Gas is a test cell dedicated to the in-situ gas analysis of battery materials in a flow-through setup. It combines all capabilities of the ECC-Air, ECC-DEMS and PAT-Cell-Press test cells. For this purpose, the test cell features a gas inlet and outlet with self-locking couplings that are compatible with 1/16 in. Swagelok tube fittings. In addition, options that include a built-in pressure sensor or a valve port for gas sampling with a syringe are also available.The cell stack is placed on top of a perforated or grooved current collector (flow field), which is to be purged with a gentle stream of gas. The lower electrode must be porous to gas to allow for gas exchange with the feed gas. The cell is typically used with gas diffusion electrodes (such as for Li-air) or with Li-ion battery electrodes with a meshed current collector. The unique design minimizes the back mixing of the gas from the flowfield back into the headspace. It is thus very suitable for time-resolved gas analysis with a mass spectrometer, for example.

All PAT-Cell-Gas variants can be operated directly with the PAT-Tester-x potentiostat. If used with a 3rd party potentiostat, the PAT-Press-Box is required for all variants equipped with a pressure sensor.

Working modes

There are two dedicated lower plunger available for the

PAT-Cell-Gas for different testing purposes.

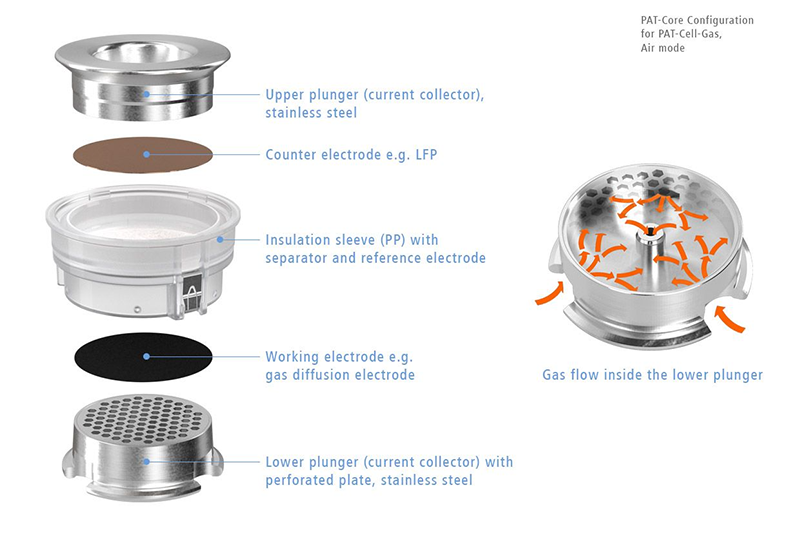

Mode 1: Air mode

The lower plunger with perforated plate allows for electrochemical characterization of gas diffusion electrodes used for instance in Li-air batteries. The lower electrode is contacted by and “breathes” through the perforated stainless steel current collector supporting it. During operation, the pressure gradient building up between cell headroom and the gas volume below the perforated plate effectively prevents back-mixing. The relatively large volume below the perforated is at the expense of time resolution, but makes this solution robust against clogging of the gas path.PAT-Core configuration example

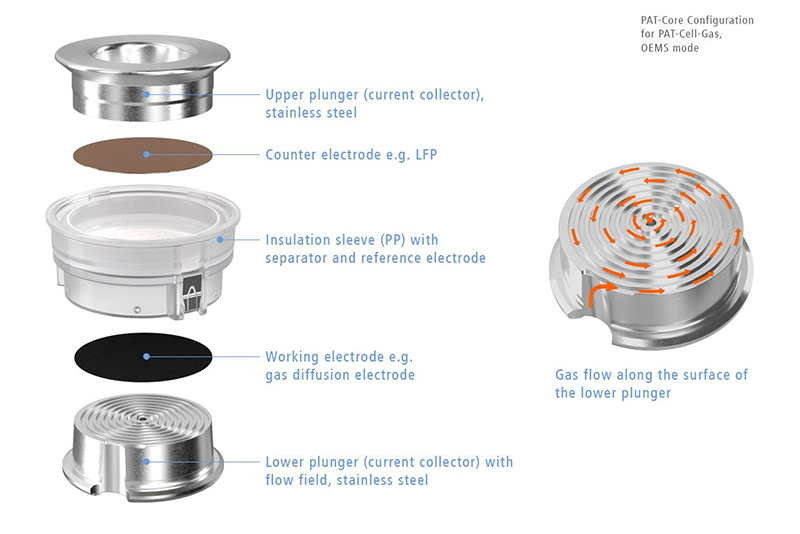

Mode 2: OEMS mode

The PAT-Core setup using a lower plunger with a flow field provides almost perfect plug-flow of the purge gas, being essential for quantitative time-resolved analysis. Gases evolved or consumed at the working electrode may be analysed through the composition change of the gas stream that is to be passed along the spiral-type flow field below the working electrode. The composition of the outgoing gas can be analyzed by e.g. mass spectrometry. The pressure gradient between cell headroom and spiral-type flow field effectively prevents back mixing. This and the tiny gas volume of the flow field ensure the best possible time resolution.PAT-Core configuration example

-

Dead volume (PAT-Cell-Gas with metal seal lid)