X射線管

X-Ray Tube 型號:Mini-X2-

Mini-X2 是一個微型 X 射線管系統,包括 X 射線管、電源、控制電子器件和與電腦的 USB 通信。 它針對緊湊型 X 射線螢光(XRF)應用進行了最佳化。 Mini-X2 通過接地陽極、USB 電流和電壓控制、簡單的准直器安裝方式以及操作簡便性簡化了 XRF 過程。

Mini-X2 由兩個元件組成:Mini-X2 X 射線管模組和 Mini-X2 控制器。 X 射線管模組包括射線管和高壓電源。有幾種不同的選項可供選擇:

最大高壓 50kV 70kV 最大功率 4W 10W 10W 陽極 Ag, Au, Rh, or W Ag, Au, Rh, or W Au, Rh, or W 控制器包括 USB 通信和軟體控制。 它可通過軟體進行配置,以支援任何 X 射線管模組。 一根 10 針軟排線將控制器和 X 射線管模組連接起來。 控制器介面包括 12 VDC 電源、用於命令和控制的 USB 以及帶有安全聯鎖和警告燈驅動程式的 AUX 介面。

Mini-X2 取代了 Amptek 以往的 Mini-X 產品系列。 X 射線管模組與以前的 Mini-X-OEM 類似。 控制器顯著改善了控制功能,包括軟體可配置性和更快的控制和回讀。 它採用完全不同的軟體介面,基於 Amptek 數位脈衝處理器使用的 FW6 協定。

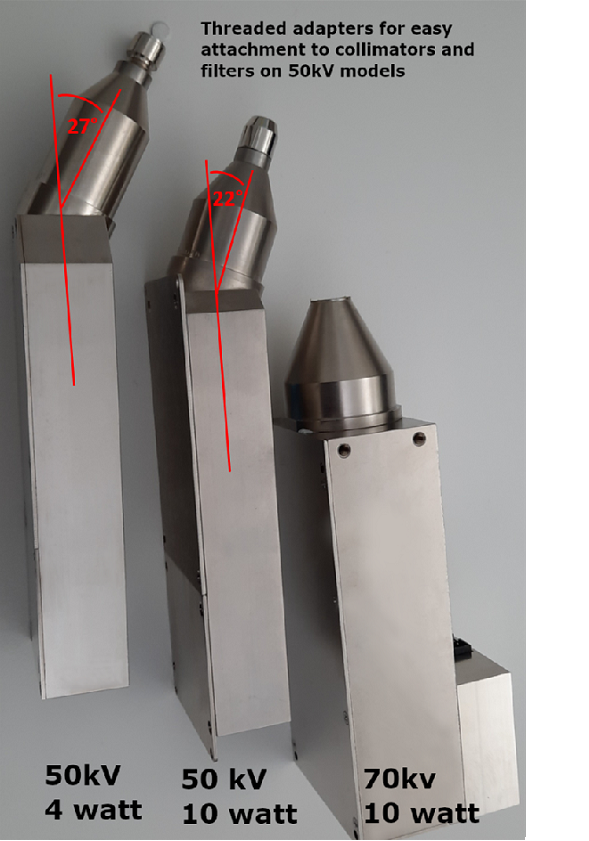

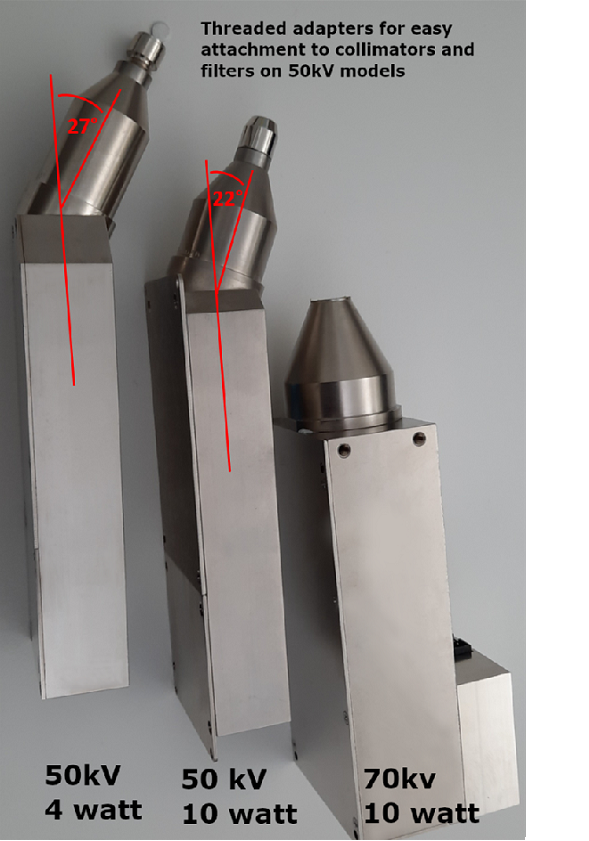

所有 50kV 型號上都有方便安裝準直器或過濾器的螺紋。

產品特點

- 4 或 10 W 輸出功率

- 10 至 50 kV 或 35 至 70 kV

- 5 至 200 μA

- Ag、Rh、Au 或 W 靶(Ag 在 70kV 下不可用)

- USB 控制

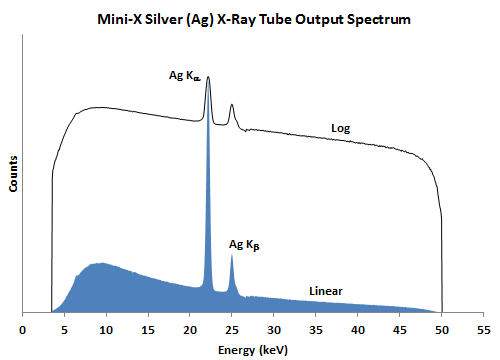

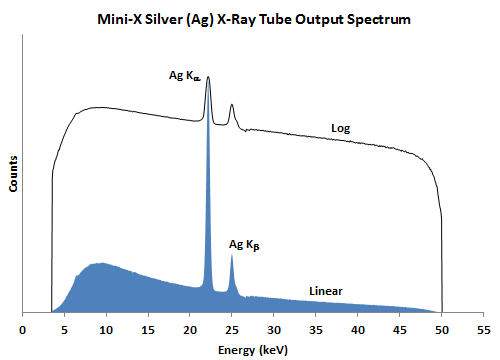

圖 1a.50 kV 下的 Mini-X2 銀(Ag)X 射線輸出光譜

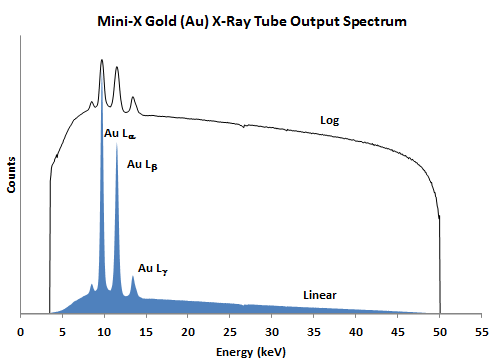

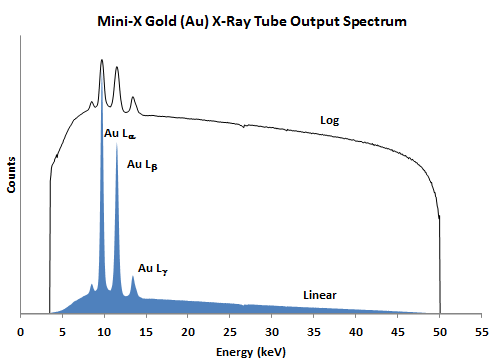

圖 1b.50 kV 下的 Mini-X2 金(Au)X 射線輸出光譜

銀(Ag)靶(左)和金(Au)靶(右)的輸出光譜。 這些光譜使用帶1 mm 針孔准直器(由鎢製成)的 1 mm 厚 CdTe 探測器距 Mini-X2 1 米處所測光譜。

產品應用- X 射線螢光(XRF)

- 可攜式和台式儀器

- 在線處理

- 教學實驗室

- 真空應用

Mini-X2 可配置一個標準真空法蘭,用於真空應用

-

靶材料

銀(Ag)、金(Au)、銬(Rh)、鎢(W)

靶厚度

Ag 和 Rh = 0.75 μm(±0.1 μm)

Au 和 W = 1.00 μm(±0.1 μm)射線管電壓

10 至 50 kV 或 35 至 70 kV

射線管電流

最小 5 μA/最大 200 μA

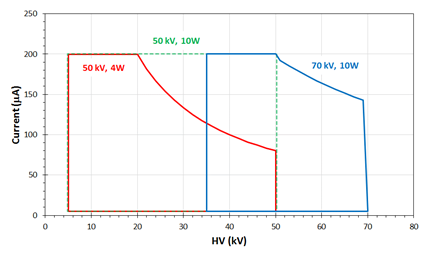

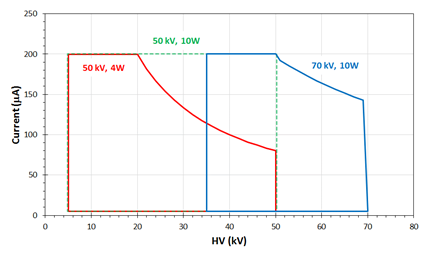

參見下面的圖 2近似劑量率

Ag 和 Rh:1 Sv/h(100 Rem/hr)@ 軸上 30 cm,50 kV 和 80 μA

Au 和 W:2.2 Sv/h(220 Rem/hr)@ 軸上 30 cm,50 kV 和 80 μA連續輸出功率

100% 佔空比時最大為 4 W 或 10 W

請參見下面的圖 2視窗材料

鈹(Be); 視窗接地

視窗厚度

127 µm

焦點大小

約 2 mm

陰極類型

鎢絲(W)

HV 極性

接地陽極

高電壓穩定性

<0.1%

輸出通量穩定性

<0.3%(溫度穩定)

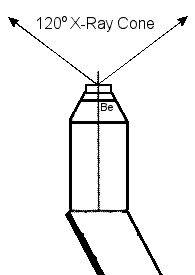

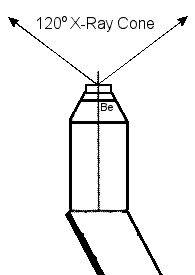

輸出錐角

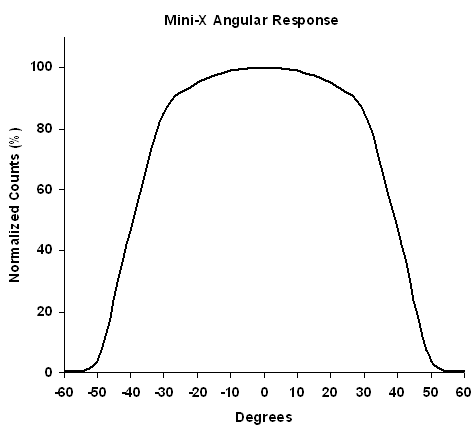

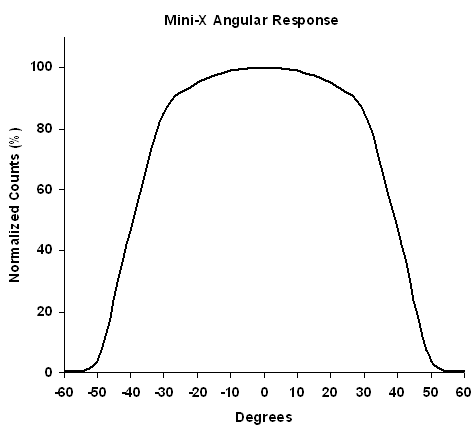

120°(請參見下面的圖 3 和圖 4)

冷卻

風冷式

5 cm 處的洩漏輻射

裝有安全塞<5 µSv/h(0.5 mrem/h)

功耗

4 W 管:9 W @ 全功率

10 W 管:18 W @ 全功率輸入電壓

12 VDC(隨附交流電源供應器)

控制

USB、mini-USB 介面(隨附電纜)

穩定時間

通常 <1 s

重量

400 g

濕度

30% 至 90%,無冷凝

工作溫度範圍

-10°C 至 +50°C

存儲溫度範圍

-25°C 至 +60°C

安全控制和指示燈

1)外部硬體聯鎖

2)閃爍 LED

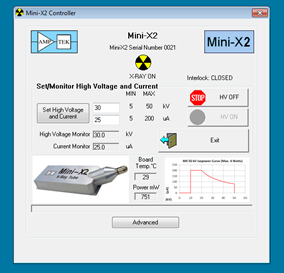

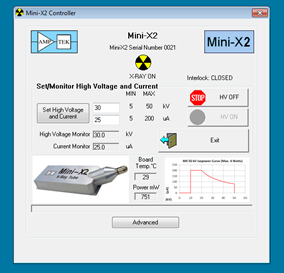

3)蜂鳴器用於控制電壓和電流的Mini-X控制軟體。

用於自定義程式應用程式的Mini-X API。保修

一年或 2000 小時,具體取決於哪一個先到

*規格可能會有所變動

圖 2.Mini-X2 等功率。 電流和電壓必須根據此曲線設置,否則 Mini-X2 可能會遭到嚴重損壞。

此類損壞不在保修範圍內。 Amptek 的控制軟體會將功率限制在此曲線上。

如果命令的系統功率超出了功率限制,軟體將使用命令的 HV 並回滾電流以符合功率限制要求。

請注意,曲線因射線管而異。

圖 3.Mini-X2 角回應,120° 錐角。

圖 4.Mini-X2 120° 錐角。

注意:當使用 2 mm 准直器時,X 射線錐角為 5°。

圖 5.Mini-X2 控制器介面。

圖 6.Mini-X2 軟體控制面板。

-

The Mini-X2 is a miniature X-ray tube system which includes the X-ray tube, the power supply, the control electronics, and the USB communications to the computer. It is optimized for compact X-ray fluorescence (XRF) applications.

The Mini-X2 consists of two components:

the Mini-X2 X-ray tube module and the Mini-X2 Controller. The X-ray tube module includes the tube and HVPS. Several different options are available:maxium HV 50kV 70kV maximum power 4W 10W 10W anode Ag, Au, Rh, or W Ag, Au, Rh, or W Au, Rh, or W The Controller includes the USB communications and software control. It can be configured, via software, to support any of the X-ray tube modules. A 10 pin flex cable connects the Controller and the X-ray tube module. Connections to the Controller are 12VDC power, USB for command and control, and an AUX connector with a safety inter- lock and a driver for a warning light.

The Mini-X2 is a replacement for Amptek’s previous Mini-X product family. The X-ray Tube Module is similar to the previous Mini-X-OEM. The Controller has significantly improved control features, including software configurability and faster control and readback. It utilizes a completely different software interface, based upon the FW6 protocol used with Amptek’s digital pulse processors.

Convenient threads for attaching collimators or filters are available on all 50kV models.

Features

- 4 or 10 W Output Power

- 10 to 50 kV or 35 to 70 kV

- 5 to 200 µA (See isopower curves)

- Ag, Rh, Au, or W Target (Ag not available in 70kV)

- USB Controlled

Figure 1a. Mini-X2 Silver (Ag) X-Ray Output Spectrum at 50 kV.

Figure 1b. Mini-X2 Gold (Au) X-ray Output spectrum at 50 kV.

Output Spectrum with silver (Ag) target (left) and gold (Au) target (right). These were measured using a 1 mm thick CdTe detector located 1 meter from the Mini-X2 with a 1 mm pinhole collimator (made from tungsten) in front of the detector.

Applications

- X-Ray Fluorescence (XRF)

- Portable and bench top instruments

- Online processing

- Teaching labs

The Mini-X2 is based on the Newton Scientific Inc. miniature X-ray source. The Mini-X2 has replaced the Mini-X(orig); for information on the original Mini-X, see this link.

-

50kV

70kV

Target Material

Silver (Ag), Gold (Au), Rhodium (Rh), Tungsten (W)

Gold (Au), Rhodium (Rh), Tungsten (W)

Target Thickness

Ag and Rh = 0.75 µm (±0.1 µm)

Au and W = 1.00 µm (±0.1 µm)Tube voltage

10 to 50 kV

35 to 70 kV

Tube current

5 µA min / 200 µA max

See Figure 2 below5 µA min / 200 µA max

See Figure 2 belowApproximate Dose Rate

Ag and Rh: 1 Sv/h (100 Rem/hr) @ 30 cm on axis, 50 kV and 80 µA

Au and W: 2.2 Sv/h (220 Rem/hr) @ 30 cm on axis, 50 kV and 80 µAdata unavailable

Continuous Output Power

4 W or 10 W max at 100% duty cycle

See Figure 2 below10 W max at 100% duty cycle

See Figure 2 belowWindow Material

Beryllium (Be); window at ground

Beryllium (Be); window at ground

Window Thickness

125 µm

125 µm

Focal Spot Size

Approximately 2 mm

Cathode Type

Tungsten (W) filament

Tungsten (W) filament

HV Polarity

Grounded anode

Grounded anode

High Voltage Stability

<0.1%

<0.1%

Output Flux Stability

<0.3% (temperature stabilized)

<0.3% (temperature stabilized)

Output Cone Angle

120° (See figures 3 and 4 below)

120° (See figures 3 and 4 below)

Cooling

Air Cooled

Air Cooled

Leakage Radiation at 5 cm

with safety plug installed<5 µSv/h (0.5 mrem/h)

no safety plug attachment

Power Consumption

4 W tubes: 9 W @ full power

10 W tubes: 18 W @ full power10 W tubes: 18 W @ full power

Input Voltage

12 VDC (AC adapter included)

12 VDC (AC adapter included)

Control

USB, mini-USB connector (cable included)

USB, mini-USB connector (cable included)

Settling Time

Typical <1 s

Typical <1 s

Weight

~400 grams

<700 grams

Humidity

30 to 90% noncondensing

30 to 90% noncondensing

Operating Temperature Range

-10 °C to +50 °C

-10 °C to +50 °C

Storage Temperature Range

-25 °C to +60 °C

-25 °C to +60 °C

Safety Controls and Indicators

1) External Hardware Interlock

2) Flashing LED

3) Beeper1) External Hardware Interlock

2) Flashing LED

3) BeeperSoftware

Mini-X2 Control software to control voltage and current.

Mini-X2 API for custom programming applications.Mini-X2 Control software to control voltage and current.

Mini-X2 API for custom programming applications.Warranty

One year or 2000 hours, whichever comes first

One year or 2000 hours, whichever comes first

Specifications, terms and pricing subject to change.

Figure 2. Mini-X2 Isopower.

The current and voltage must be set in accordance with this curve or the Mini-X2 may be severely damaged. Damage of this kind is not covered under warranty. Amptek’s control software limits the power to this curve. If one commands the system to a power exceeding the power limit, the software will use the commanded HV and rollback the current to meet the power limit. Note that the curves differ based on the tube.

Figure 3. Mini-X2 Angular Response, 120° cone.

Figure 4. Mini-X2 120° cone.

NOTE: The x-ray cone angle can be reduced when using collimators, see below for approximate references.

Figure 5. Mini-X2 Controller connectors.

Figure 6. Mini-X2 software control panel.