最小燃燒壓力裝置

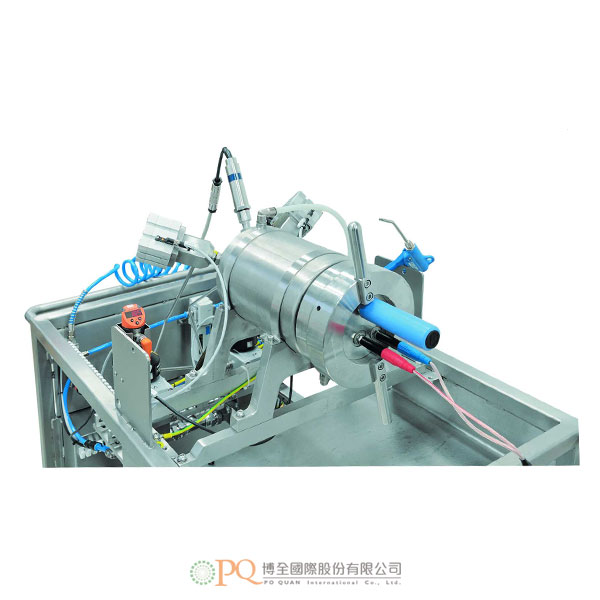

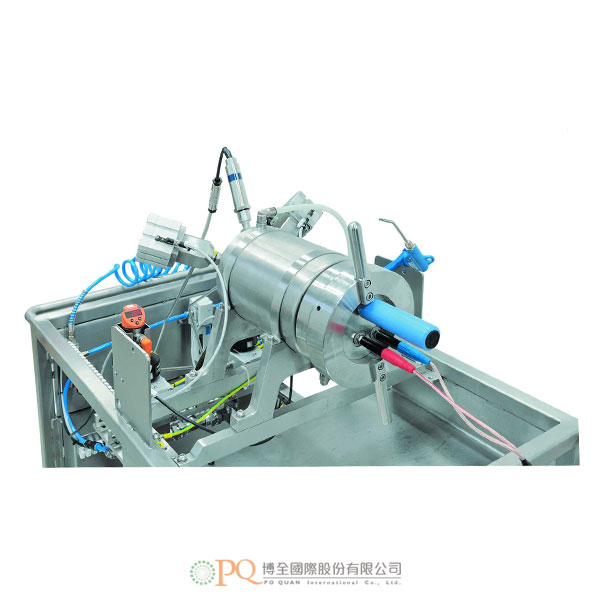

Minimum Burning Pressure Apparatus 型號:MBPMBP 是市場上首款同類型設備在提高硝酸銨炸藥的安全性方面邁出了一大步。它是一種通用、使用簡單、易於評估的解決方案,經久耐用,既適用於生產和科學實驗。

-

MBP最小燃燒壓力裝置)用於測試在高壓條件下封閉容器中用熱絲點燃的乳化炸藥的最小燃燒壓力。MBP 是 OZM與加拿大爆炸物研究實驗室 (CERL) 合作開發的乳化炸藥先進穩定性和敏感度測試的全新方法。

MBP 是市場上首款同類型設備在提高硝酸銨炸藥的安全性方面邁出了一大步。它是一種通用、使用簡單、易於評估的解決方案,經久耐用,既適用於生產和科學實驗。

應用

雖然乳化炸藥的處理通常相當安全,但與之相關的事故

仍時有發生,而傳統的穩定性或敏感度測試方法不足以

發現其危險行為。

經研究發現,大多數事故都是在材料的泵送、製造或運輸

過程中承受高壓和高溫時發生的。因此,確定最小燃燒壓

力已成為乳化炸藥最重要的安全特性之一。MBP 主要用於測試乳化炸藥在開發和工業生產過程中的

敏感度。同時,使用 MBP 進行的小規模試驗可提供有關

乳化炸藥安全泵送壓力的重要資訊。另外,MBP 也可用於

其它可能承受壓力和溫度負荷的爆炸物。

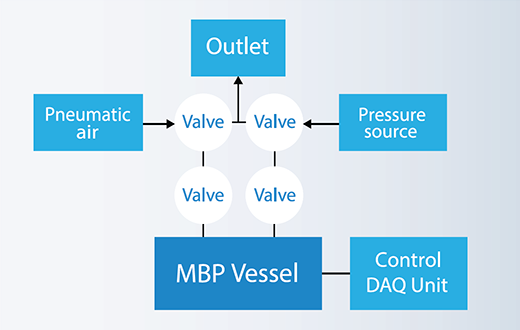

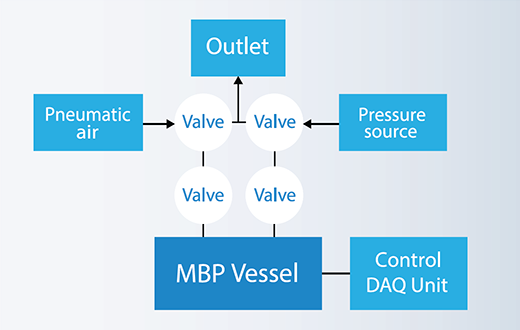

MBP 容器基本架構

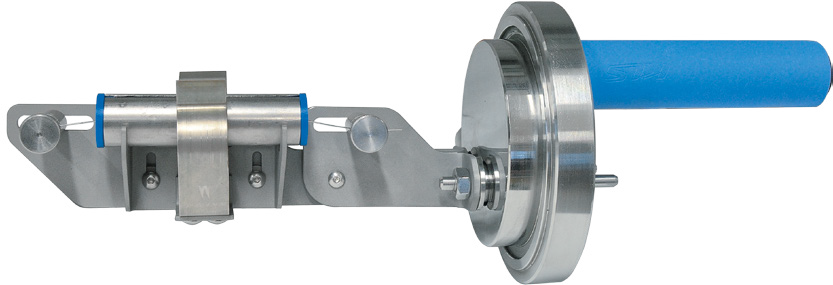

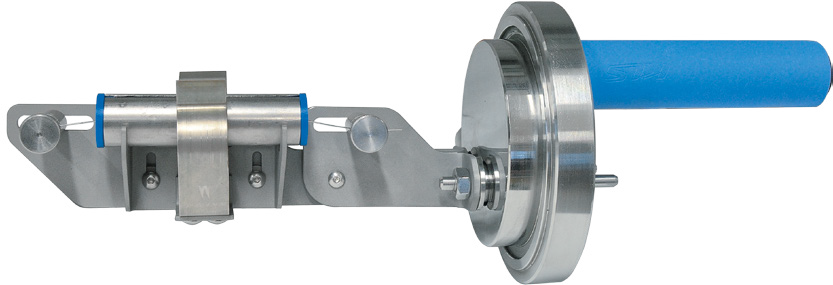

帶樣品架的 MBP 艙蓋優勢和特點

- 由經認證的非腐蝕性材料製成的密閉容器。

- 工作壓力高達 500 bar(帶遠端遙控的壓力歧管)。

- 精確的恆定電流電源,用於樣品的熱點火。

- 分解時間、分解末期的壓力和分解速率的測量。

- 易於操作、耐用、一體式設計、連接簡單,

並配有使用者友好的數據處理軟體。

MBP 測量與控制單元 -

The MBP™ (Minimum Burning Pressure Apparatus) is used for the determination of the minimum burning pressure of emulsion explosives ignited by a hot wire in a closed vessel under high pressure conditions. The MBP is a completely new approach to advanced stability and sensitivity testing of emulsion explosives, developed in cooperation between OZM Research and the Canadian Explosives Research Laboratory (CERL). The MBP is the very first equipment of its kind on the market and it represents a huge step forward for the safety improvement of ammonium nitrate based explosives. It’s a universal, simple-to-use and easy to evaluate solution made durable for both production and scientific experiments.

APPLICATIONS

While emulsion explosives are normally quite safe for

handling, accidents connected with them are still

occurring and conventional methods of stability or

sensitivity testing are not representative enough to

discover their risky behavior. It has been found that

most of the accidents happened when the materials

were subjected to elevated pressures and

temperatures during their pumping, manufacturing or

transport. The determination of the minimum burning

pressure has therefore become one of the most

important safety characteristics of emulsion

explosives. The MBP is primarily designed for testing

sensitivity of emulsion explosives during both their

development and industrial manufacture. Small-scale

tests with MBP can provide very important

information about the emulsion explosive safe

pumping pressure. The MBP can also be used for

other explosives, which are likely to be subjected to

pressure and temperature loads.

MBP vessel basic scheme

MBP lid with the sample holderADVANTAGES & FEATURES

- Certified closed vessel from a noncorrosive

material - Working pressure up to 500 bar

(with a remotely controlled pressure manifold) - Precise constant current power supply for thermal

ignition of the sample - Measurement of time-to-decomposition, terminal

pressure of decomposition and decomposition

rate - Easy to handle, heavy duty, one-box design with

simple connectivity and user-friendly software for

data processing

MBP measurement and control unit - Certified closed vessel from a noncorrosive