-

жЏ╗тїќтГИ / ТЮљТќЎ / тё▓УЃйУБЮуй«ТИгУЕд

- УќёУєюжЏ╗тїќтГИТёЪТИгтЎе

- уюЪуЕ║жЇЇУєюу│╗ух▒

- ТјїСИітъІжЏ╗тїќтГИтёђ

- тќ«жђџжЂЊТЂњжЏ╗СйЇ№╝ЈТЂњжЏ╗ТхЂ№╝ЈС║цТхЂжў╗ТіЌтѕєТъљтёђ

- тцџжђџжЂЊТЂњжЏ╗СйЇ№╝ЈТЂњжЏ╗ТхЂ№╝Ј С║цТхЂжў╗ТіЌтѕєТъљтёђ

- жФўтіЪујЄтцџжђџжЂЊТЂњжЏ╗СйЇ№╝ЈТЂњжЏ╗ТхЂ№╝ЈС║цТхЂжў╗ТіЌтѕєТъљтёђ

- жЏ╗Т▒атЁЁТћЙжЏ╗тѕєТъљтёђ

- жЏ╗тїќтГИ/УЁљУЮЋ/УЃйТ║љтѕєТъљ

- жЏ╗тїќтГИжЁЇС╗Х

- ТЂєТ║ФТЂєТ┐Ћ/Т░БТ░Џуѕљ/УЕджЕЌу«▒

- уЄЃТќЎжЏ╗Т▒ауаћуЕХ

- тљФУЃйТЮљТќЎТИгУЕдтѕєТъљ

- жЏ╗Т▒аТИгУЕдтѕєТъљ

- ТХ▓ТхЂжЏ╗Т▒ауаћуЕХ

- уёАуиџтЈ»Тћют╝ЈжЏ╗тїќтГИ

- жІ░жЏ╗Т▒аУБйуеІ

- ує▒тЃЈтёђтЎеТЄЅуће

- тцфжЎйУЃйтЁЅС╝ЈуЏИжЌюУеГтѓЎ

- жјќуЏИТћЙтцДтЎе

-

жЏ╗тіЏУеГтѓЎТИгУЕд

- УХЁжЪ│Т│бТфбТИгтёђ

- жбетіЏуЎ╝жЏ╗ТЕЪуХГУГиТИгУЕд

- У«ітБЊтЎеТИгУЕд

- жЏ╗у║юТИгУЕд

- GIS/жќІжЌюТИгУЕд

- жЃеС╗йТћЙжЏ╗уЏБТИг/Уе║Тќи

- уЎ╝жЏ╗ТЕЪ/ждгжЂћТИгУЕд

- У«іжЏ╗ТЅђУеГтѓЎТИгУЕд

- ухЋуиБ/УђљтБЊ/жФўтБЊТ║љ

- СйјжЏ╗жў╗жЄЈТИгтёђтЎе

- ТјЦтю░жЏ╗жў╗жЄЈТИгтёђтЎе

- СИђУѕгжЏ╗тіЏТИгжЄЈтёђУАе

- жЏ╗тіЏтЊЂУ│ф/УФДТ│буЏБТИгтѕєТъљ

- жЏ╗тіЏуХГУГиУеГтѓЎ

- у┤ФтцќуиџТћЙжЏ╗тй▒тЃЈТфбТИгтёђ

- У│ЄТќЎУњљжЏє

- Т║Фт║д/жЏ╗жЄЈ/тБЊтіЏ/Тї»тІЋ ТИгжЄЈТаАТГБ

- жЏ╗уБЂТ│бт«ЅтЁе

- уЅЕуљєт»джЕЌУеГтѓЎ

- тЪ║уцјуаћуЕХУеГтѓЎ

- жЮъуа┤тБъТфбТИгУеГтѓЎ

-

жЏ╗тїќтГИ / ТЮљТќЎ / тё▓УЃйУБЮуй«ТИгУЕд

- УќёУєюжЏ╗тїќтГИТёЪТИгтЎе

- уюЪуЕ║жЇЇУєюу│╗ух▒

- ТјїСИітъІжЏ╗тїќтГИтёђ

- тќ«жђџжЂЊТЂњжЏ╗СйЇ№╝ЈТЂњжЏ╗ТхЂ№╝ЈС║цТхЂжў╗ТіЌтѕєТъљтёђ

- тцџжђџжЂЊТЂњжЏ╗СйЇ№╝ЈТЂњжЏ╗ТхЂ№╝Ј С║цТхЂжў╗ТіЌтѕєТъљтёђ

- жФўтіЪујЄтцџжђџжЂЊТЂњжЏ╗СйЇ№╝ЈТЂњжЏ╗ТхЂ№╝ЈС║цТхЂжў╗ТіЌтѕєТъљтёђ

- жЏ╗Т▒атЁЁТћЙжЏ╗тѕєТъљтёђ

- жЏ╗тїќтГИ/УЁљУЮЋ/УЃйТ║љтѕєТъљ

- жЏ╗тїќтГИжЁЇС╗Х

- ТЂєТ║ФТЂєТ┐Ћ/Т░БТ░Џуѕљ/УЕджЕЌу«▒

- уЄЃТќЎжЏ╗Т▒ауаћуЕХ

- тљФУЃйТЮљТќЎТИгУЕдтѕєТъљ

- жЏ╗Т▒аТИгУЕдтѕєТъљ

- ТХ▓ТхЂжЏ╗Т▒ауаћуЕХ

- уёАуиџтЈ»Тћют╝ЈжЏ╗тїќтГИ

- жІ░жЏ╗Т▒аУБйуеІ

- ує▒тЃЈтёђтЎеТЄЅуће

- тцфжЎйУЃйтЁЅС╝ЈуЏИжЌюУеГтѓЎ

- жјќуЏИТћЙтцДтЎе

-

жЏ╗тіЏУеГтѓЎТИгУЕд

- УХЁжЪ│Т│бТфбТИгтёђ

- жбетіЏуЎ╝жЏ╗ТЕЪуХГУГиТИгУЕд

- У«ітБЊтЎеТИгУЕд

- жЏ╗у║юТИгУЕд

- GIS/жќІжЌюТИгУЕд

- жЃеС╗йТћЙжЏ╗уЏБТИг/Уе║Тќи

- уЎ╝жЏ╗ТЕЪ/ждгжЂћТИгУЕд

- У«іжЏ╗ТЅђУеГтѓЎТИгУЕд

- ухЋуиБ/УђљтБЊ/жФўтБЊТ║љ

- СйјжЏ╗жў╗жЄЈТИгтёђтЎе

- ТјЦтю░жЏ╗жў╗жЄЈТИгтёђтЎе

- СИђУѕгжЏ╗тіЏТИгжЄЈтёђУАе

- жЏ╗тіЏтЊЂУ│ф/УФДТ│буЏБТИгтѕєТъљ

- жЏ╗тіЏуХГУГиУеГтѓЎ

- у┤ФтцќуиџТћЙжЏ╗тй▒тЃЈТфбТИгтёђ

- У│ЄТќЎУњљжЏє

- Т║Фт║д/жЏ╗жЄЈ/тБЊтіЏ/Тї»тІЋ ТИгжЄЈТаАТГБ

- жЏ╗уБЂТ│бт«ЅтЁе

- уЅЕуљєт»джЕЌУеГтѓЎ

- тЪ║уцјуаћуЕХУеГтѓЎ

- жЮъуа┤тБъТфбТИгУеГтѓЎ

LUBExpert УХЁжЪ│Т│бТйцТ╗Љт░ѕт«Х

тъІУЎЪ№╝џLUBExpert- У╗ИТЅ┐ТЋИТЊџт║Ф: LUBExpertуХГУГиТѓеТЅђТюЅУ│ЄућбуџёТЋИТЊџт║Ф№╝їтїЁТІгУ╗ИТЅ┐жАътъІтњїт░║т»Исђѓ

- УЄфтІЋтїќ: LUBExpertУЄфтІЋУеѕу«ЌТйцТ╗ЉТ│хС╣ІжќЊуџёуЕЕт«џТЎѓжќЊсђѓ

- т╝Ћт░јтњїУЄфжЂИТеАт╝Ј:LUBExpertТЈљСЙЏтЁЕуе«ТйцТ╗ЉУ╗ИТЅ┐уџёТќ╣т╝Ј№╝џ “УЄфжЂИ”тњї“ТїЄт░ј”сђѓ уёАУФќТѓет░ЇуеІт╝ЈуєЪТѓЅжѓёТў»тЅЏжќІтДІ№╝їLUBExpertжЃйУЃйт╣ФтіЕТѓеТГБуб║ТйцТ╗ЉУ╗ИТЅ┐сђѓ

- ТйцТ╗ЉтіЉт╗║УГ░: LUBExpertТЈљжєњТѓеуѓ║ТЌЦтИИТйцТ╗ЉС╗╗тІЎТЈљСЙЏТГБуб║уџёТйцТ╗ЉтіЉжАътъІтњїТЋИжЄЈсђѓ

- тиЦСйюТЈљжєњ: LUBExpertТюЃТЈљжєњТѓеС╗ітцЕтЊфС║ЏУ╗ИТЅ┐жюђУдЂТйцТ╗ЉсђѓС┐ЮТїЂТйцТ╗ЉуеІт╝ЈуџёуДЕт║Јтњїу┤ђтЙІсђѓ

- у│╗ух▒УеіТЂ»:LUBExpertСй┐ућеУеіТЂ»СЙєУеўжїёТќЄТфћСИдт╗║УГ░ТѓеуџётюўжџіТюЅС╗ђж║╝тиЦСйютњїУ│ЄућбУбФУи│жЂјсђѓ

-

ТйцТ╗ЉСИЇУЅ»Тў»У╗ИТЅ┐ТЋЁжџюуџёСИ╗УдЂтјЪтЏа

Уе▒тцџжюђТйцТ╗ЉућбтЊЂтИИУдЂтюеТЌЦуеІУеѕуЋФтцќжђ▓УАїжАЇтцќТйцТ╗Љ№╝їжђЎт░▒т░јУЄ┤С║єУ╗ИТЅ┐жЄЇУцЄТйцТ╗Љ№╝їжђЎт░ЄуёАТ│ЋжФћуЈЙт«ЃтђЉуџётиЦуеІтЃ╣тђ╝сђѓ

LUBExpertТйцТ╗Љт░ѕт«ХтЉіУе┤ТѕЉтђЉСйЋТЎѓУЕ▓ТйцТ╗ЉтЈіСйЋТЎѓУЕ▓тЂюТГбТйцТ╗ЉУ╗ИТЅ┐ТйцТ╗ЉтЈ»С╗ЦТИЏт░ЉТЉЕТЊд№╝їУ╝Ѓт░ЉуџёТЉЕТЊдТёЈтЉ│УЉЌТЏ┤жЋиуџёСй┐ућетБйтЉй№╝їLUBExpertТюЃТЈљжєњТѓеТЉЕТЊдтЇЄжФўуџёТЎѓжќЊ№╝їтюеТѓежЄЇТќ░ТйцТ╗ЉуџёТЎѓтђЎТЈљжєњТѓе№╝їжў▓ТГбжЄЇУцЄТйцТ╗Љсђѓ

- У╗ИТЅ┐ТЋИТЊџт║Ф: LUBExpertуХГУГиТѓеТЅђТюЅУ│ЄућбуџёТЋИТЊџт║Ф№╝їтїЁТІгУ╗ИТЅ┐жАътъІтњїт░║т»Исђѓ

- УЄфтІЋтїќ: LUBExpertУЄфтІЋУеѕу«ЌТйцТ╗ЉТ│хС╣ІжќЊуџёуЕЕт«џТЎѓжќЊсђѓ

- т╝Ћт░јтњїУЄфжЂИТеАт╝Ј:LUBExpertТЈљСЙЏтЁЕуе«ТйцТ╗ЉУ╗ИТЅ┐уџёТќ╣т╝Ј№╝џ “УЄфжЂИ”тњї“ТїЄт░ј”сђѓ уёАУФќТѓет░ЇуеІт╝ЈуєЪТѓЅжѓёТў»тЅЏжќІтДІ№╝їLUBExpertжЃйУЃйт╣ФтіЕТѓеТГБуб║ТйцТ╗ЉУ╗ИТЅ┐сђѓ

- ТйцТ╗ЉтіЉт╗║УГ░: LUBExpertТЈљжєњТѓеуѓ║ТЌЦтИИТйцТ╗ЉС╗╗тІЎТЈљСЙЏТГБуб║уџёТйцТ╗ЉтіЉжАътъІтњїТЋИжЄЈсђѓ

- тиЦСйюТЈљжєњ: LUBExpertТюЃТЈљжєњТѓеС╗ітцЕтЊфС║ЏУ╗ИТЅ┐жюђУдЂТйцТ╗ЉсђѓС┐ЮТїЂТйцТ╗ЉуеІт╝ЈуџёуДЕт║Јтњїу┤ђтЙІсђѓ

- у│╗ух▒УеіТЂ»:LUBExpertСй┐ућеУеіТЂ»СЙєУеўжїёТќЄТфћСИдт╗║УГ░ТѓеуџётюўжџіТюЅС╗ђж║╝тиЦСйютњїУ│ЄућбУбФУи│жЂјсђѓ

ТГБуб║уџёТйцТ╗ЉтіЉ

СИЇтљїуџёТЄЅућежюђУдЂСИЇтљїуџёТйцТ╗ЉтіЉсђѓLUBExpertтіЕТЅІтЈ»С╗Цт╣ФтіЕТѓежЂИТЊЄТГБуб║уџёТйцТ╗ЉтіЉ№╝їСИдТЈљжєњТѓеУ╗ИТЅ┐уџёТюђтцДућежЄЈсђѓ

ТГБуб║уџёСйЇуй«

УІЦтљїТЎѓжюђУдЂу«АуљєтцџтђІУ│ЄућбУеГтѓЎ№╝їТѓетдѓСйЋуб║т«џУЄфти▒тЪиУАїуџёТў»ТГБуб║уџёУ╗ИТЅ┐ТйцТ╗Љ№╝Ъ LUBExpertуџётіЕТЅІСй┐ућеUASуџёТе╣уІђухљТДІт░јУѕфтЇћтіЕТѓеу«АуљєТЋ┤тђІтиЦт╗асђѓ

ТГБуб║уџёжќЊжџћ

уёАУФќТѓеТў»тЪ║Тќ╝СЙІУАїуџёТйцТ╗ЉжѓёТў»ТбЮС╗ХуџёТйцТ╗Љ№╝їLUBExpertтњїUltranalysis SuiteжЃйТюЃтюеУ╗ИТЅ┐жюђУдЂТйцТ╗ЉТЎѓТЈљжєњТѓесђѓ ућ▒SDTуџёжђ▓тїќтЏЏТЁІТїЄТеЎУДИуЎ╝уџёУГдта▒тЈ»уб║С┐ЮУеГтѓЎуџєТїЅТЎѓТйцТ╗Љсђѓ

ТГБуб║уџётіЉжЄЈ

ТйцТ╗ЉжЂјтцџтњїТйцТ╗ЉСИЇУХ│Тў»ТюђтИИУдІУѕЄТйцТ╗ЉТюЅжЌюуџёТЋЁжџюуџётјЪтЏасђѓ LUBExpertтіЕТЅІТюЃжђБу║їУеѕу«ЌтЁЕТгАТйцТ╗ЉС╣ІжќЊуџёТЉЕТЊдТЋИтђ╝№╝їт╗║УГ░ТѓеТи╗тіаТЏ┤ТйцТ╗ЉтіЉТѕќУђЁтюежЂћтѕ░ТюђСй│ТЉЕТЊдуІђТЁІТЎѓтЂюТГбу╣╝у║їТйцТ╗Љсђѓ

ТГБуб║уџёТїЄТеЎ

LUBExpertт░ЇуЏБТјДТйцТ╗ЉУ╗ИТЅ┐уџёС╗╗тІЎтЁЁТ╗┐С┐Ат┐Ѓсђѓ тіЕТЅІТюЃТїЄт░јТѓежаєтѕЕт«їТѕљС╗╗тІЎ№╝їСИдСЙЮтЪиУАїухљТъютЙЌтЄ║УЅ»тЦйсђЂСИЇУЅ»ТѕќтЈ»уќЉуџёухљУФќсђѓ Т┤╗тІЋУбФУеўжїётюеUAS SuiteТЋИТЊџу«АуљєУ╗ЪС╗ХСИГ№╝їУЕ▓У╗ЪжФћжА»уц║ТйцТ╗ЉтЅЇтЙїуџёти«уЋ░сђЂТ»ЈтђІж╗ъТи╗тіауџёТйцТ╗ЉтіЉТЋИжЄЈС╗ЦтЈіжЃежќђТѕќтиЦт╗аТХѕУђЌуџёТйцТ╗ЉтіЉуИйжЄЈсђѓ -

тіЪсђђсђђУЃй

тцџтіЪУЃйУХЁжЪ│Т│бТјбТИгтёђ

жА»сђђсђђуц║

жФўУДБТъљт║дсђЂтИХУЃїтЁЅLCD№╝ї128×64тюќтЁЃ

жЇхсђђсђђуЏц

12тђІтіЪУЃйжЇх

тЁДуй«ТёЪТИгтЎе

УХЁжЪ│Т│бТёЪТИгтЎесђЂу┤ЁтцќуиџТ║Фт║дТёЪТИгтЎе

тцќуй«ТёЪТИгтЎе

жђџжЂјуЅ╣т«џуџёжђБТјЦтЎе№╝ѕLEMO7жЄЮт╝ЈжђБТјЦтЎе№╝Ѕ

У│ЄТќЎУеўжїё

LUBExpert УѕЄУ│ЄТќЎт║ФУ╗ЪжФћUASжЁЇтљѕСй┐ућесђѓТИгжЄЈУХЁжЂј10000тђІжЮюТЁІУ│ЄТќЎТИгжЄЈу»ђж╗ъ№╝їтІЋТЁІТИгжЄЈ№╝ѕУеўжїёТ│бтйб№╝Ѕ№╝џ13тѕєжљўсђѓ

жђџ Уеі

У│ЄТќЎтЈ»СИІУ╝ЅУЄ│жЏ╗УЁдСИдућеUASУ╗ЪжФћтѕєТъљ

жЏ╗ Т║љ

жЏ╗Т▒атЁЁжЏ╗№╝џ4.8V 4400 mAhжј│Т░ФжЏ╗Т▒асђѓ

Сй┐ућеТЎѓжќЊ№╝џ8тђІт░ЈТЎѓ№╝ѕСй┐ућеУЃїтЁЅТюЃТИЏт░ЉТЎѓжќЊ№╝Ѕсђѓ

ТеЎТ║ќт«╣жЄЈ№╝џ4.4AhсђѓтБйтЉй№╝џ500-1000ТгАтЁЁжЏ╗/ТћЙжЏ╗сђѓ

С┐ЮУГи№╝џуЪГУи»сђЂтЈЇТјЦТѕќТ║Фт║дС┐ЮУГиУЄфтІЋжЌюТЕЪ

жаљУеГТЎѓжќЊУЄфтІЋжЌюТЕЪ

тиЦСйюТ║Фт║д

-15РёЃтѕ░+60РёЃ

тцќсђђсђђТ«╝

У╗ІУБйжІЂТЮљ№╝їТЕАуџ«С┐ЮУГитЦЌ

т░║сђђсђђт»И

226 x 40 x 90 mm№╝ѕL x H x W№╝Ѕ

жЄЇсђђсђђжЄЈ

у┤ё830тЁІ№╝ѕтљФжЏ╗Т▒атњїуџ«тЦЌ№╝Ѕ

-

Poor greasing practices are a leading cause of bearing failure. Less than 40% of bearings will last long enough to deliver their engineered value and over or under lubrication is most often to blame.

Many lube departments re-grease on a wasteful calendar-based schedule. This leads to over and under greased bearings that fail to deliver their engineered value.

Grease reduces friction in bearings. Less friction means longer life. LUBExpert alerts you when friction levels increase, guides you during re-lubrication, and prevents over and under lubrication.

LUBExpert is an ultrasound solution that helps you Grease Bearings Right. Use the right lubricant at the right location using the right intervals and the right quantities while receiving the right indication of a task well done including bearing status.

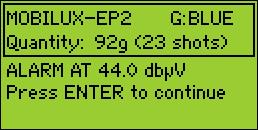

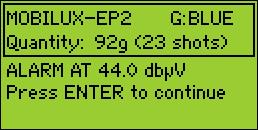

The LUBExpert is a complete ultrasound solution to manage your acoustic lubrication program and ensure you GREASE BEARINGS RIGHT- Bearing Database№╝џLUBExpert maintains a database of all your assets including bearing type and dimensions.

- Automation№╝џLUBExpert removes the guesswork by automatically calculating the stabilization time between grease pumps.

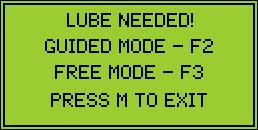

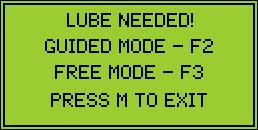

- Guided & Free Modes№╝џLUBExpert offers two modes to grease bearings right; “free” and “guided”. Whether your program is mature, or just getting started LUBExpert helps you grease bearings right.

- Shopping List№╝џLUBExpert reminds you to bring the right grease type and the right quantity for the days lube tasks.

- Work Orders№╝џLUBExpert reminds you which bearings need grease today. Restore order and discipline to your lubrication program.

- System Messaging№╝џLUBExpert uses messaging to document and advise your team whay and asset was skipped.

The RIGHT LUBRICANT

Different applications require different lubricants. Which one is the right one? LUBExpert’s onboard assistant helps you select the correct grease and reminds you of the bearing’s maximum capacity.

The RIGHT LOCATION

With potentially thousands of assets to manage, how can you be sure you’re greasing the right bearings? LUBExpert’s onboard assistant guides you through your plant using UAS’s tree structured navigation.

The RIGHT INTERVAL

Whether you lubricate on a calendar-based or condition-based schedule, LUBExpert and Ultranalysis Suite alert you when bearings are due for relubrication. Alarms triggered by SDT’s evolutionary FOUR CONDITION INDICATORS make sure the “squeaky wheel” gets the grease on time.

The RIGHT QUANTITY

Over and under lubrication are to blame for most lubrication related failures. LUBExpert’s onboard assistant continuously calculates friction levels between half shots of grease advising you to add more – or stop when optimal friction levels are reached.

The RIGHT INDICATORS

LUBExpert delivers confidence to the task of re-greasing bearings. The onboard assistant guides you smoothly through the task and concludes with a GOOD, BAD, or SUSPECT result. Activities are tied back into UAS Suite data management software where logical reports illustrate before and after, quantity of grease added per point, and total grease consumed by department or plant. -

Operable with SDT LUBEsense1 Temperature measurement Measuring range: -70 to +380°C / -94 to +716°F

Accuracy 0 to 50°C / 32 to 122°F ± 0.5 °C / ± 32.9 °F(/br)

Field of view (attenuation of 50%): 10°/Memory capacity/td> Linux Data collector Memory capacity: More than 10,000 data distributed over more

than 10,000 measurement locations.CPU ARM9 @ 400MHz Display Graphic backlighted LCD (128 x 64) Internal memory DDR2, 256 Mb Housing Extruded aluminum, shock proof rubber protections Data memory 256 Mb Dimensions 226 x 90 x 40 mm / 8.90 x 3.54 x 1.57 in (L x W x H) Signal processing Dynamic range: 109 dB, Resolution: 16 bits,

Sampling rate: 256 kHzWeight 830 g / 29.3 oz, including battery Ultrasound measurement Measuring range: -15 to 120 dBµV

(reference 0 dB = 1 µV)

Resolution: 0.1 dBµVSNR: -6dB

Bandwidth: 36.1 to 40.4 kHzBattery Rechargeable NiMH battery.

Capacity 4.4Ah. 8h Autonomy ( without backlight)