A4300 VA3 Pro三通道振動分析儀

型號:A4300 VA3 Pro- 針對路徑測量的完美設計

- 大的電池容量保證長時間連續運行

- 重量僅780g

- 路徑內存:8GB

- 彩色顯示幕 : 240 x 320像素

- 用戶可定制需要的測量功能

-

A4300 VA3 Pro是我們用於振動診斷的便攜式設備系列的最新成員。有2個信號輸入和1個測速/觸發輸入。

輸入2提供與三軸傳感器輸入的連接,因此可以同時測量所有3個頻道。

Adash開發的專家系統可以自動檢測機器故障,如- 不平衡、錯位、 鬆動、軸承故障。

同時配置一個非接觸式紅外溫度感測器,可即時測量軸承溫度以及一個LED頻閃儀/手電筒。

A4300 VA3 Pro專為單手操作而設計。該裝置重量僅為780g,電池壽命超過10小時,適合長時間路徑測量。

A4300 VA3 Pro儀器可根據您的要求進行配置選擇可選功能:包含分析、路徑、動平衡、啟動分析或超音波。

選購功能也可另外購買並下載到儀器中開通使用,無需將其送回工廠升級。

訪問Adash官網,查看更多可靠性設備。

主要特點 :- 針對路徑測量的完美設計

- 大的電池容量保證長時間連續運行

- 重量僅780g

- 路徑內存:8GB

- 彩色顯示幕 : 240 x 320像素

- 用戶可定制需要的測量功能

主選單A4300 VA3 Pro可以根據您的需求配置功能功能。每個VA3都包含三個標準功能:振動表、專家系統及閃頻儀。另外有一些可選的測量功能:

主選單A4300 VA3 Pro可以根據您的需求配置功能功能。每個VA3都包含三個標準功能:振動表、專家系統及閃頻儀。另外有一些可選的測量功能:

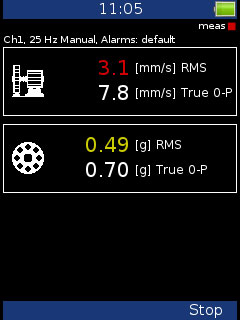

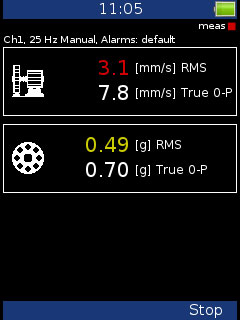

如分析、路徑、動平衡、紀錄分析、啟動分析或超音波分析。 振動表 - 標準功能!振動表項目包括基本振動測量模式:振動總量值(RMS,0-PEAK)

振動表 - 標準功能!振動表項目包括基本振動測量模式:振動總量值(RMS,0-PEAK)

FFT頻譜

時域波形

頻帶

位移

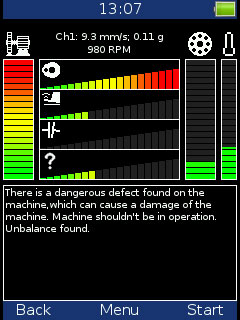

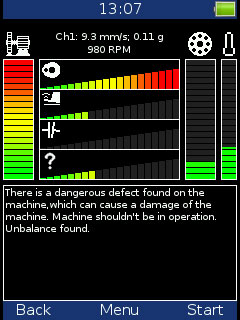

溫度 FASIT ( 專家系統 ) -標準功能!FASIT(故障根源識別工具)是一種自動檢測設備故障的專家系統:

FASIT ( 專家系統 ) -標準功能!FASIT(故障根源識別工具)是一種自動檢測設備故障的專家系統:

不平衡

錯位

鬆動

軸承故障 閃頻儀 - -標準功能!打開閃頻儀,直觀地“凍結”設備運動並檢查其旋轉部件並可以檢測設備的轉速。

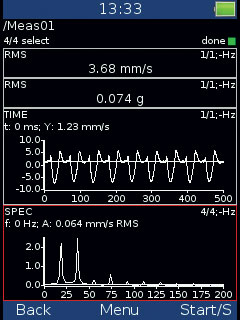

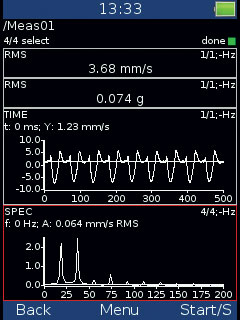

閃頻儀 - -標準功能!打開閃頻儀,直觀地“凍結”設備運動並檢查其旋轉部件並可以檢測設備的轉速。 分析選擇測量類型(從簡單的振動總量值到FFT和時域波形,再到電渦流傳感器的更高級測量,如軸心軌跡),根據您的要求設置測量參數(頻率範圍,取樣,單位等)並同步蒐集所有預定義的測量模式。

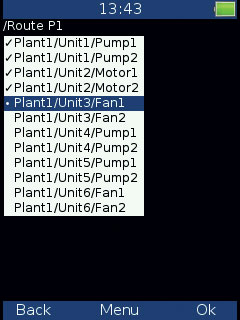

分析選擇測量類型(從簡單的振動總量值到FFT和時域波形,再到電渦流傳感器的更高級測量,如軸心軌跡),根據您的要求設置測量參數(頻率範圍,取樣,單位等)並同步蒐集所有預定義的測量模式。 路徑路徑功能用於工廠設備的日常巡檢及數據收集。只需在DDS軟件中建立帶有測量點位置的路徑樹(也可以在免費的DDS版本中),並定期進行測量。將蒐集的數據傳輸到DDS軟件以觀察趨勢並分析數據。

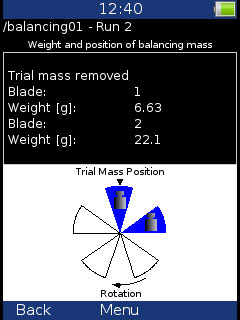

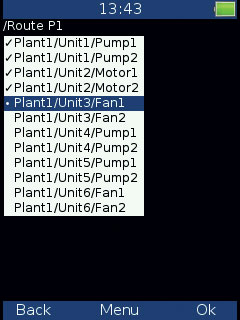

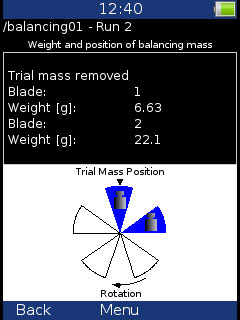

路徑路徑功能用於工廠設備的日常巡檢及數據收集。只需在DDS軟件中建立帶有測量點位置的路徑樹(也可以在免費的DDS版本中),並定期進行測量。將蒐集的數據傳輸到DDS軟件以觀察趨勢並分析數據。 動平衡動平衡功能允許您執行旋轉部件的單面或雙面平衡工作,例如工業風機,鼓風機,主軸等。

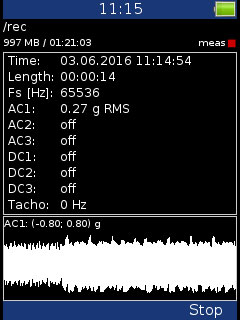

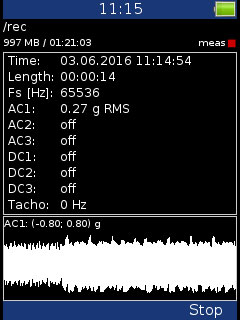

動平衡動平衡功能允許您執行旋轉部件的單面或雙面平衡工作,例如工業風機,鼓風機,主軸等。 紀錄分析特有的測量模式用於變化的工況以及無法預測的狀況。紀錄器功能用來“記錄”來自傳感器的原始信號,表示來自設備的原始信號。這允許稍後在PC上對信號進行後處理。您可以反複播放此記錄並對其應用任何測量設置。

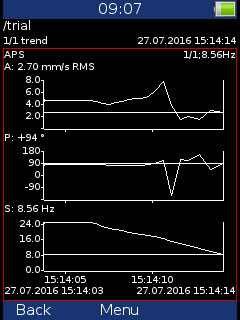

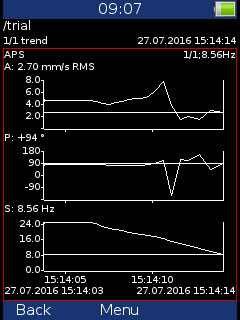

紀錄分析特有的測量模式用於變化的工況以及無法預測的狀況。紀錄器功能用來“記錄”來自傳感器的原始信號,表示來自設備的原始信號。這允許稍後在PC上對信號進行後處理。您可以反複播放此記錄並對其應用任何測量設置。 啟動分析與分析模式類似,可以在其中設置任何您需要的測量參數。同時也能夠允許您控制數據的保存方式,例如盡快、或根據速度變化、時間變化等。

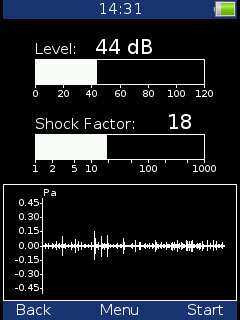

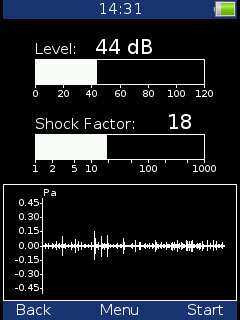

啟動分析與分析模式類似,可以在其中設置任何您需要的測量參數。同時也能夠允許您控制數據的保存方式,例如盡快、或根據速度變化、時間變化等。 超音波分析測量人耳無法聽到的聲音- 超音波。典型應用是洩露檢測、電弧或早期軸承故障檢測。

超音波分析測量人耳無法聽到的聲音- 超音波。典型應用是洩露檢測、電弧或早期軸承故障檢測。 -

Input channels

3 x AC, ICP® power supply on/off

3 x DC for process values

1 x TACHO for speed probe / external triggerInput range

AC +/- 12 V peak-peak

DC +/- 24VAD conversion

24 bit, 64 bit internal signal processing

No AutoGain function!Dynamic range S/N

120 dB

Frequency ranges (-3 dB)

Maximum range: 0.5 Hz - 25 kHz (64 kHz sampling)

Minimum range: 0.5 Hz - 25 Hz (64 Hz sampling)Sampling mode

Fully simultaneous for all 3 channels

FFT resolution

Min. 25 lines

Max. 25 600 linesMeasurement modes

Analyzer - analytical measurements

Data collector - route measurements

Balancer - 1 and 2 plane on site balancing

Recorder - raw signal recording for later post analysis

Run Up - run up and coast down measurements

Ultrasound - measurement of ultrasound in 30 - 50 kHz range

LED stroboscope, LED torch

FASIT - Expert system for automatic fault detection

Vibration meter - basic vibration measurementsSoftware

Free version of DDS software (limited database size)

Licensed DDS softwareData processing

Real time FFT

DEMOD - ENVELOPE analysis

ACMT - low speed bearing analysis

Order analysis

User band pass analysis

RPM measurement

DC measurement

Orbit measurementIR temperature measurement

From -70˚C to +380˚C (-94˚F to +716˚F)

Trigger

Manual, External, Amplitude, Tacho

Display

Colour 240 x 320 pixels, TFT

Interface

USB 2.0, 3.0 compatible

Operating temperature range

-10˚C to +50˚C

Power

Battery pack for more than 10 hours of continous operation

Case

Aluminium - heavy duty

Weight

780 g

Dimensions

230 x 82 x 32 mm

-

The A4300 VA3 Pro is the newest addition to our range of portable devices for vibration diagnostics.

There are 2 signal inputs and 1 tacho/trigger input. Input 2 offers connectivity to a triaxial sensor, therefore all 3 channels can be measured simultaneously. The expert system developed by Adash can automatically detect machine faults susuch as unbalance, looseness, misalignment and bearing faults.

There is a non-contact IR temperature sensor (for immediate bearing temperature measurement) and a LED stroboscope/torch. The A4300 VA3 Pro is designed for one-handed operation. With a weight of just 780g and a battery life of more than 10 hours of operation, the unit is suitable for long route measurements. The A4300 VA3 Pro instrument can be configured according to your requirements by choosing optional modules: analyzer, route, balancer, recorder, run up or ultrasound. Optional mmoo dules can be purchased also additionally and downloaded to the instrument without the need of sending it back to the factory.

Please see more at www.adash.com and come back to us for further assistance with your purchase.

Features- Low weight 780 g

- Long lasting battery

- Ideal for route measurement

- Route compatibility with VA4 Pro

Main menuThe A4300 VA3 Pro instrument can be configured according to your requirements by choosing measuring modules. There are three free modules included in every VA3: Meter, Fasit and Strobo. Other modules are optional: Analyzer, Route, Balancer, Recorder, Run Up or Ultrasound.

Main menuThe A4300 VA3 Pro instrument can be configured according to your requirements by choosing measuring modules. There are three free modules included in every VA3: Meter, Fasit and Strobo. Other modules are optional: Analyzer, Route, Balancer, Recorder, Run Up or Ultrasound. Meter - Free Module!The Meter module includes basic vibration measurement screens:

Meter - Free Module!The Meter module includes basic vibration measurement screens:

Overall Vibration Values (RMS, 0-PEAK)

FFT Spectrum

Time Signal

Frequency Bands

Displacement

Temperature FASIT - Free Module!

FASIT - Free Module!

FASIT (Fault Source Identification Tool) is an expert system for automatic detection of possible machine faults:

Unbalance

Misalignment

Looseness

Bearing faults Strobo - Free Module!

Strobo - Free Module!

Switch on the stroboscope to visually “freeze” the machine movement and check its rotating parts. The speed of the machine can be detected. Analyzer

Analyzer

Select the type of the measurement (from simple overall values through FFTs and time signals to more advanced measurements with Proximity probes such as Orbits), set up the measurement settings according to your requirements (frequency range, sampling, units etc.) and take all the predefined measurements simultaneously. Route

Route

The route module is used for day to day data collection of your factory machinery. Simply create your route tree with measurement points location in the DDS software (possible also in the free DDS version) and take the measurements regularly. Transfer the collected data to DDS software to watch the trends and analyze the data. Balancer

Balancer

The balancer allows you to perform one or two plane balancing job of rotating parts such as industrial fans, blowers, spindles etc. Recorder

Recorder

A unique measurement mode with unappreciated value. Recorder “records” the raw signal from the sensor, means raw signal from the machine. This allows to make a post processing of the signal later on your PC. You can play this record again and again and apply any measurement setting to it. Run up

Run up

Similar to Analyzer mode where you can setup any measurement which you like. RunUp allows you to control the saving of data for example as soon as possible, or by speed change, time change etc. Ultrasound

Ultrasound

Measurement of sound inaudible to the human ear – ultrasound. Typical application are air leak detection, electrical arcing or early bearing fault detection. -

Input channels

3 x AC, ICP® power supply on/off

3 x DC for process values

1 x TACHO for speed probe / external triggerInput range

AC +/- 12 V peak-peak

DC +/- 24VAD conversion

24 bit, 64 bit internal signal processing

No AutoGain function!Dynamic range S/N

120 dB

Frequency ranges (-3 dB)

Maximum range: 0.5 Hz - 25 kHz (64 kHz sampling)

Minimum range: 0.5 Hz - 25 Hz (64 Hz sampling)Sampling mode

Fully simultaneous for all 3 channels

FFT resolution

Min. 25 lines

Max. 25 600 linesMeasurement modes

Analyzer - analytical measurements

Data collector - route measurements

Balancer - 1 and 2 plane on site balancing

Recorder - raw signal recording for later post analysis

Run Up - run up and coast down measurements

Ultrasound - measurement of ultrasound in 30 - 50 kHz range

LED stroboscope, LED torch

FASIT - Expert system for automatic fault detection

Vibration meter - basic vibration measurementsSoftware

Free version of DDS software (limited database size)

Licensed DDS softwareData processing

Real time FFT

DEMOD - ENVELOPE analysis

ACMT - low speed bearing analysis

Order analysis

User band pass analysis

RPM measurement

DC measurement

Orbit measurementIR temperature measurement

From -70˚C to +380˚C (-94˚F to +716˚F)

Trigger

Manual, External, Amplitude, Tacho

Display

Colour 240 x 320 pixels, TFT

Interface

USB 2.0, 3.0 compatible

Operating temperature range

-10˚C to +50˚C

Power

Battery pack for more than 10 hours of continous operation

Case

Aluminium - heavy duty

Weight

780 g

Dimensions

230 x 82 x 32 mm