-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

Automatic Research

Automatic Research

-

AWSensors

AWSensors

-

BASI

BASI

-

BRS

BRS

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Cmc

Cmc

-

C-Tech

C-Tech

-

CTRL

CTRL

-

DANATRONICS

DANATRONICS

-

DV Power

DV Power

-

EA Technology

EA Technology

-

ECH

ECH

-

EL-CELL

EL-CELL

-

Electrothermal

Electrothermal

-

Elsys

Elsys

-

ELVEFLOW

ELVEFLOW

-

Enapter

Enapter

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Enervac

Enervac

-

FASTEC

FASTEC

-

Gaskatel

Gaskatel

-

GE

GE

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GMW

GMW

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HTW

HTW

-

HUBER

HUBER

-

HVPD

HVPD

-

Ida

Ida

-

Instytut Fotonowy

Instytut Fotonowy

-

IVIUM

IVIUM

-

Jacomex

Jacomex

-

Jenway

Jenway

-

JGG

JGG

-

KEHUA TECH

KEHUA TECH

-

Labdex

Labdex

-

Labnics

Labnics

-

LIQUID

LIQUID

-

METERTEST

METERTEST

-

Metrel

Metrel

-

Microrad

Microrad

-

micrux

micrux

-

ndb

ndb

-

Neware

Neware

-

Norecs

Norecs

-

Novocontrol

Novocontrol

-

OKOndt Group

OKOndt Group

-

OZM

OZM

-

Pine Research

Pine Research

-

Redoxme

Redoxme

-

SATIR

SATIR

-

SDT

SDT

-

Serstech

Serstech

-

VacCoat

VacCoat

-

Zurich

Zurich

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- Automatic Research

- AWSensors

- BASI

- BRS

- CALMET

- CHECKLINE

- Cmc

- C-Tech

- CTRL

- DANATRONICS

- DV Power

- EA Technology

- ECH

- EL-CELL

- Electrothermal

- Elsys

- ELVEFLOW

- Enapter

- ENERGY SUPPORT

- Enervac

- FASTEC

- Gaskatel

- GE

- GIUSSANI

- Globecore

- GMW

- GREENLIGHT

- GRZ

- HIGH SENSE SOLUTIONSHTW

- HTW

- HUBER

- HVPD

- Ida

- Instytut Fotonowy

- IVIUM

- Jacomex

- Jenway

- JGG

- KEHUA TECH

- Labdex

- Labnics

- LIQUID

- METERTEST

- Metrel

- Microrad

- micrux

- ndb

- Neware

- Norecs

- Novocontrol

- OKOndt Group

- OZM

- Pine Research

- Redoxme

- SATIR

- SDT

- Serstech

- VacCoat

- Zurich

-

由於使用了PEEK(聚醚醚酮 ,或稱Teflon),Elveflow的這個全新的進階版微流體除泡器現在可以進行高壓滅菌。在此基礎上,其主體仍然具有生物相容性。

通過與工程師和研究人員的合作,一個新的設計應運而生。這種新的微流體除泡器具有穩定、堅固、便於使用,以及確保了防漏的設置。

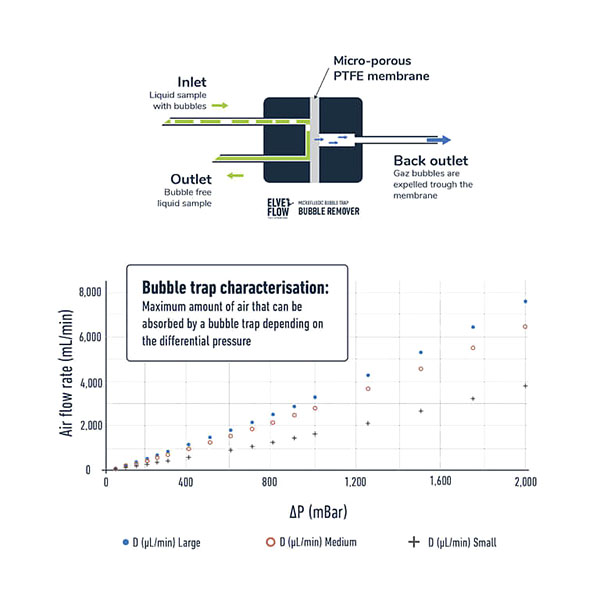

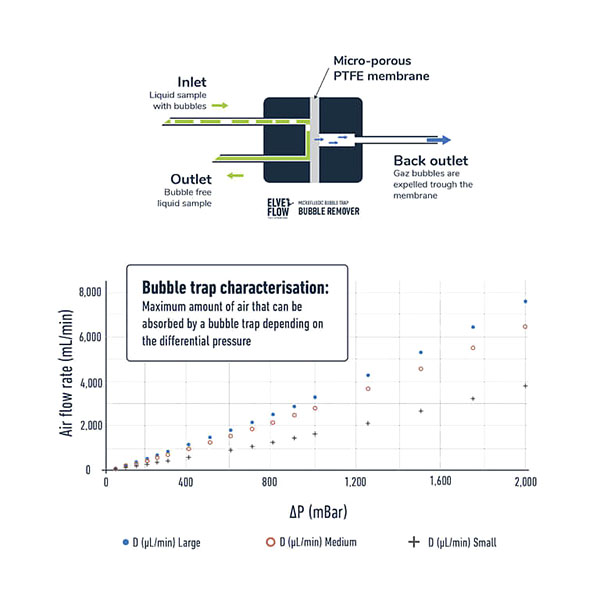

該微流體除泡器具有Teflon膜。將含有氣泡的溶液推入除泡器中,並通過微孔Teflon膜以無洩漏的方式除去氣泡。 您可以選擇將真空泵連接到除泡器的後部出口(主動模式)以增加除泡器的性能。 但即使沒有連接泵(被動模式),除泡器通常在大多數實驗裝置中仍然顯示出出色的消除氣泡之性能。

最後,微流體除泡器具有2種模式使用:被動模式和可以添加真空管路的主動模式。 在第二種模式下,壓力產生器的真空出口,可最大化提高除泡器的效率。 該除泡器能夠實現100%的脫泡,流量可達60 mL/min。 該微流體除泡器通常在0.5-2.0 mL/min的範圍內使用,但是當使用真空管線時可以達到60 mL/min。

工作原理

-

標準套件包含:

1×:微流體除泡器*

三個不同版本(內部體積):23 μL(S)-95 μL(M)-362 μL(L)。 該設備正面有兩個1/4″-28 UNF內螺紋埠 ( 適用於1/8″、1/16″或1/32″外徑管子 ),用於連接流體流和一個額外的1/4″-28 UNF內螺紋介面,如果需要,可在側面進行真空連接。

1×:更換膜片

膜片使用時間可能是幾個月或幾年。 建議在使用後用去離子水/蒸餾水沖洗除泡器,以防止膜片過早老化。 -

This new and improved version of Elveflow’s bubble trap is now autoclavable, thanks to the use of PEEK (Polyetheretherketone). On top of this, the body remains biocompatible.

A new design came to life from working together with engineers and researchers. Stable, sturdy and user-friendly, this new bubble trap ensures leak-proof setups.

The bubble trap uses a micro-porous PTFE membrane. When a fluid containing gas bubbles flows through the trap, the bubbles are expelled through the hydrophobic membrane that allows absolutely no aqueous liquid to leak. It is possible to get rid of bubbles in a fluid even with a small pressure difference across the membrane.

The liquid sample has to be pushed towards the bubble trap inlet and not aspirated from the trap outlet to avoid cavitation issues (generating bubbles).

This bubble trap can be used in two modes: a passive mode, and an active mode where a vacuum line can be added. In this second mode, the vacuum outlet of a pressure generator, such as the OB1 Mk3, can be used to maximize the bubble trap efficiency.

This bubble trap can be used with or without vacuum assistance, and a vacuum source such as the OB1 MK3+ can be connected to maximize the bubble trap’s efficiency. This trap is typically used in the range of 0.5 – 2.0 ml/min, but up to 60ml/min can be achieved when a vacuum line is used.

-

- Robust: chemically resistant and biocompatible (PEEK body & PTFE membranes: 10µm pores), autoclavable

- Easy change of membranes (2 included) to avoid contaminations between runs

- Different internal volume versions suited to your needs

- 23µL (S)

- 95µL (M)

- 362 µL (L)

- Typical working flow rate range: down to 5μL/min and up to 6 ml/min (indicative values)

- Threaded ports: Standard 1/4″-28 Fittings suited for 1/8″, 1/16” or 1/32” OD tubing

- Pressure rating: 2 bar (30psi)

- Dimensions: a 47x34x28 mm L-shaped, stable accessory