-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

Automatic Research

Automatic Research

-

AWSensors

AWSensors

-

BASI

BASI

-

BRS

BRS

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Cmc

Cmc

-

C-Tech

C-Tech

-

CTRL

CTRL

-

DANATRONICS

DANATRONICS

-

DV Power

DV Power

-

EA Technology

EA Technology

-

ECH

ECH

-

EL-CELL

EL-CELL

-

Electrothermal

Electrothermal

-

Elsys

Elsys

-

ELVEFLOW

ELVEFLOW

-

Enapter

Enapter

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Enervac

Enervac

-

FASTEC

FASTEC

-

Gaskatel

Gaskatel

-

GE

GE

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GMW

GMW

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HTW

HTW

-

HUBER

HUBER

-

HVPD

HVPD

-

Ida

Ida

-

Instytut Fotonowy

Instytut Fotonowy

-

IVIUM

IVIUM

-

Jacomex

Jacomex

-

Jenway

Jenway

-

JGG

JGG

-

KEHUA TECH

KEHUA TECH

-

Labdex

Labdex

-

Labnics

Labnics

-

LIQUID

LIQUID

-

METERTEST

METERTEST

-

Metrel

Metrel

-

Microrad

Microrad

-

micrux

micrux

-

ndb

ndb

-

Neware

Neware

-

Norecs

Norecs

-

Novocontrol

Novocontrol

-

OKOndt Group

OKOndt Group

-

OZM

OZM

-

Pine Research

Pine Research

-

Redoxme

Redoxme

-

SATIR

SATIR

-

SDT

SDT

-

Serstech

Serstech

-

VacCoat

VacCoat

-

Zurich

Zurich

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- Automatic Research

- AWSensors

- BASI

- BRS

- CALMET

- CHECKLINE

- Cmc

- C-Tech

- CTRL

- DANATRONICS

- DV Power

- EA Technology

- ECH

- EL-CELL

- Electrothermal

- Elsys

- ELVEFLOW

- Enapter

- ENERGY SUPPORT

- Enervac

- FASTEC

- Gaskatel

- GE

- GIUSSANI

- Globecore

- GMW

- GREENLIGHT

- GRZ

- HIGH SENSE SOLUTIONSHTW

- HTW

- HUBER

- HVPD

- Ida

- Instytut Fotonowy

- IVIUM

- Jacomex

- Jenway

- JGG

- KEHUA TECH

- Labdex

- Labnics

- LIQUID

- METERTEST

- Metrel

- Microrad

- micrux

- ndb

- Neware

- Norecs

- Novocontrol

- OKOndt Group

- OZM

- Pine Research

- Redoxme

- SATIR

- SDT

- Serstech

- VacCoat

- Zurich

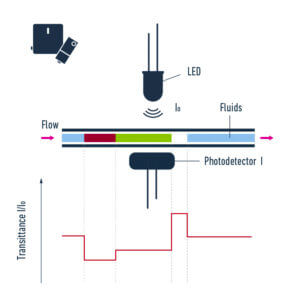

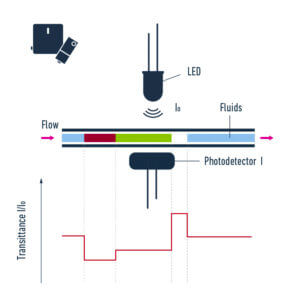

微流體氣泡檢測器 - MBD

MICROFLUIDIC BUBBLE DETECTOR - MBD 型號:MBD- 液體界面檢測

用於真/假邏輯的檢測 - 氣泡檢測

在造成問題之前檢測並避免氣泡的產生

-

流體界面的光學微流體檢測器

高精度流量監測和控制特點

線上流體感測器當前最受歡迎的應用是將該感測器用作微流體氣泡檢測器。氣泡是微流體技術中需要解決的一個大難題,因為它們會誘發流動修改或與實驗相互作用,對樣品造成損害。用戶可以在其設置的任何給定點監測和計算微流體氣泡的通過情況,並相應地實現實驗的自動化。例如,當與OB1 MK3+配對時,有可能增加壓力或切換一個微流控閥,將氣泡引向另一個流體路徑。

優點

- 可靠的非侵入性技術

- 與相機檢查相比更具有成本效益

- 用於真/假邏輯檢測

- 相容性高:管材尺寸範圍廣

- 用於任何地方使用

- 防止氣泡破裂對細胞的損害

- 設置自動化:可以根據氣泡檢測訊號來觸發流體控制操作

線上流體感測器可以直接接在Elveflow的OB1 MK3+上,也可以和感測器讀取裝置一起作為一個獨立的單元使用。

-

工作原理

Inline Fluid Sensor 檢測原理是基於光路的測量以及當流動介質變化時該光路的變化。

光束由已知功率的 LED 發出,該光束穿過毛細管和流過的流體,然後由 NPN 矽光電晶體管收集,將光功率轉換為電信號。當流體發生變化時,光學指數和光吸收係數也隨之變化。它引起電力的變化並允許判斷流體的變化。

-

optical microfluidic detector of fluid interfaces

HIGHLIGHTS

The most-popular application for the Inline Liquid Sensor is to use the sensor as a microfluidic bubble detector. Bubbles are a big challenge to address in microfluidics, as they can induce flow modifications or interact with the experiment and damage to the sample. Users can monitor and count the passage of microfluidic bubbles at any given point of their setup and automate the experiment accordingly.

For example, when paired with an OB1 MK3+ it is possible to increase the pressure or switch a valve to direct the bubbles into another fluidic path.

BENEFITS

- Reliable non invasive technique

- Cost effective compared to camera check

- Based on true/false logic

- Large compatibility: wide range of tubing size

- Use anywhere in your setup

- Prevents damage in cells with bubble bursts

- Setup automation: it is possible to trigger fluid control operations based on the bubble detection signal

The Inline Fluid Sensor can be plugged directly onto Elveflow’s OB1

More application information, please refer to the link: https://www.elveflow.com/microfluidic-products/microfluidics-flow-measurement-sensors/microfluidic-bubble-detector-inline-liquid-sensor/#tab-applications

-

PRINCIPLE OF OPERATION

The Inline Fluid Sensor detection principle is based on the measurement of the optical path and the variation of this path when the flowing medium is changing.

A light beam is emitted by a LED of known power. This light beam goes through the capillary and the fluid flowing through. It is then collected by an NPN silicon phototransistor which converts the light power into an electrical signal. When a the fluid changes, the optical index and the light absorption coefficient change accordingly. It induces a change in the electrical power and allows detection of changes in the fluid.