-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

Automatic Research

Automatic Research

-

AWSensors

AWSensors

-

BASI

BASI

-

BRS

BRS

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Cmc

Cmc

-

C-Tech

C-Tech

-

CTRL

CTRL

-

DANATRONICS

DANATRONICS

-

DV Power

DV Power

-

EA Technology

EA Technology

-

ECH

ECH

-

EL-CELL

EL-CELL

-

Electrothermal

Electrothermal

-

Elsys

Elsys

-

ELVEFLOW

ELVEFLOW

-

Enapter

Enapter

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Enervac

Enervac

-

FASTEC

FASTEC

-

Gaskatel

Gaskatel

-

GE

GE

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GMW

GMW

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HTW

HTW

-

HUBER

HUBER

-

HVPD

HVPD

-

Ida

Ida

-

Instytut Fotonowy

Instytut Fotonowy

-

IVIUM

IVIUM

-

Jacomex

Jacomex

-

Jenway

Jenway

-

JGG

JGG

-

KEHUA TECH

KEHUA TECH

-

Labdex

Labdex

-

Labnics

Labnics

-

LIQUID

LIQUID

-

METERTEST

METERTEST

-

Metrel

Metrel

-

Microrad

Microrad

-

micrux

micrux

-

ndb

ndb

-

Neware

Neware

-

Norecs

Norecs

-

Novocontrol

Novocontrol

-

OKOndt Group

OKOndt Group

-

OZM

OZM

-

Pine Research

Pine Research

-

Redoxme

Redoxme

-

SATIR

SATIR

-

SDT

SDT

-

Serstech

Serstech

-

VacCoat

VacCoat

-

Zurich

Zurich

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- Automatic Research

- AWSensors

- BASI

- BRS

- CALMET

- CHECKLINE

- Cmc

- C-Tech

- CTRL

- DANATRONICS

- DV Power

- EA Technology

- ECH

- EL-CELL

- Electrothermal

- Elsys

- ELVEFLOW

- Enapter

- ENERGY SUPPORT

- Enervac

- FASTEC

- Gaskatel

- GE

- GIUSSANI

- Globecore

- GMW

- GREENLIGHT

- GRZ

- HIGH SENSE SOLUTIONSHTW

- HTW

- HUBER

- HVPD

- Ida

- Instytut Fotonowy

- IVIUM

- Jacomex

- Jenway

- JGG

- KEHUA TECH

- Labdex

- Labnics

- LIQUID

- METERTEST

- Metrel

- Microrad

- micrux

- ndb

- Neware

- Norecs

- Novocontrol

- OKOndt Group

- OZM

- Pine Research

- Redoxme

- SATIR

- SDT

- Serstech

- VacCoat

- Zurich

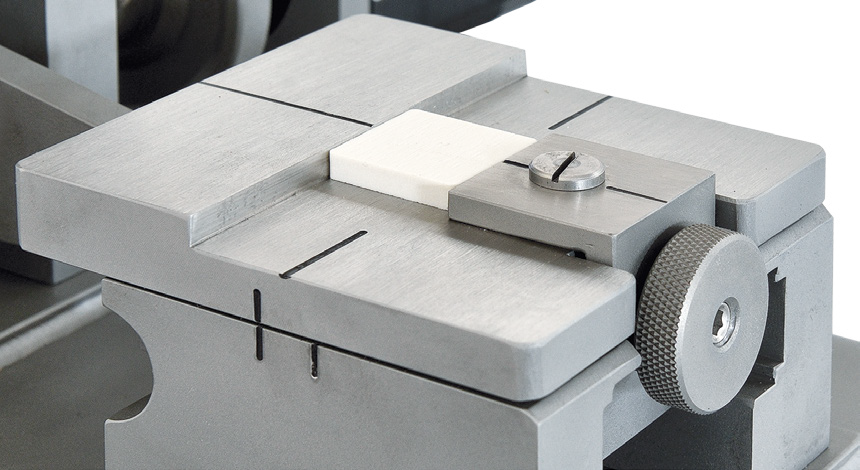

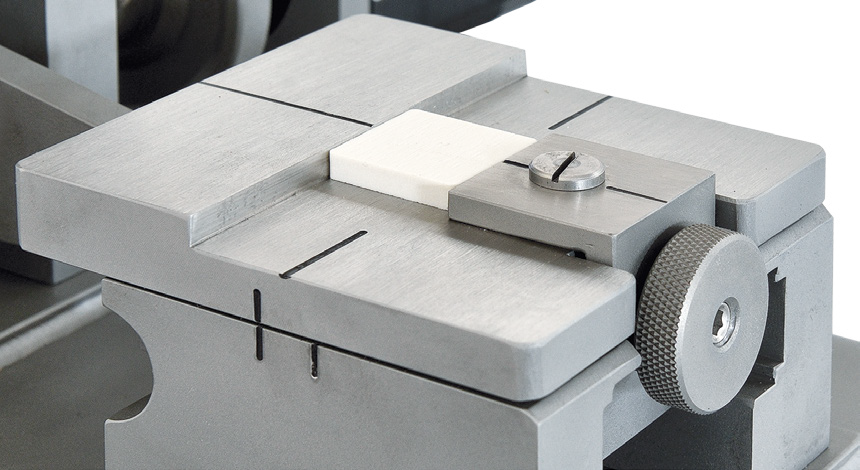

摩擦敏感度測試儀

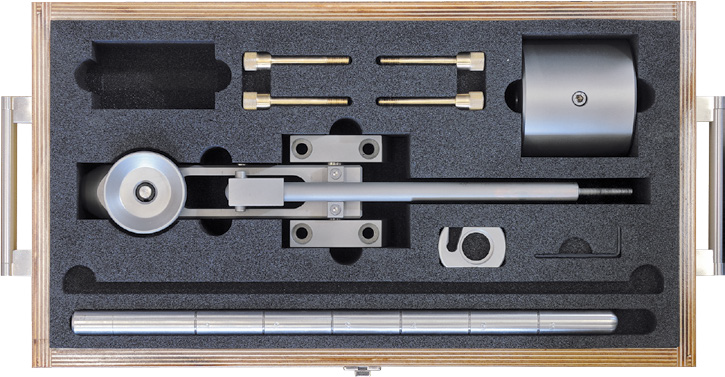

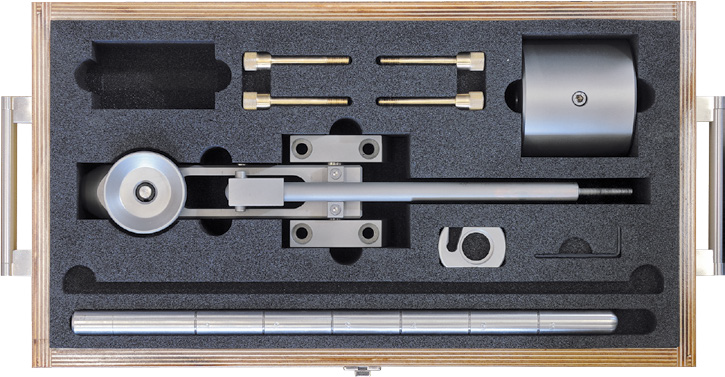

Friction Sensitivity Tester 型號:FSKM10FSKM 10 採用堅固的不銹鋼框架,配備獨特的可互換裝荷重臂裝置。有了這種裝置,所有類型的高能量材料都可以在這台設備上進行測試。

-

摩擦敏感度測試儀- FSKM 10 設計用於測量被測物質在 0.1 N 至 360 N 寬廣摩擦荷重範圍內對摩擦刺激的敏感度。

FSKM 10 採用堅固的不銹鋼框架,配備獨特的可互換裝荷重臂裝置。有了這種裝置,所有類型的高能量材料都可以在這台設備上進行測試。

應用堅硬表面之間的摩擦是導致意外爆炸的最常見原因之一。 同時,被測物質的摩擦敏感度根據標準化BAM來決定。

優勢和特點

- 獨特的可更換荷重臂概念。

- 荷重臂上6個槽口位置,可配有兩組砝碼產生 0.5 N 至 360 N 的荷重。

- 或者選擇輕型的 3個槽口位置的荷重臂,專為測試高敏感物質而設計,並配有兩組砝碼,可產生 0.1 N 至 98 N 的荷重。

- 安全防護罩可防止試驗碎片從瓷板或瓷棒處濺出,保證實驗人員操作安全。

- 數位控制式的步進馬達可實現瓷板載台的高精度移動。

- 防靜電的不銹鋼試驗平臺:檯面覆蓋有導靜電功能的橡膠,可防止樣品意外受到靜電放電作用發生爆炸,保證實驗人員操作安全。

- 瓷板載台的轉速可在20至300轉/分鐘之間調整。

- 緊急停止鍵:可快速停止儀器的運轉,保證實驗人員操作安全和儀器運行安全。

- 使用觸控螢幕控制儀器進行試驗,操作更簡單,更安全。

- 高品質的耗材,價格實惠。

瓷板載台 6個槽口位置的荷重臂組件 ( BAM 6A ) 符合

- UN Recommendation on the Transport of Dangerous Goods, Manual of Tests and Criteria, [13.4.2 Test 3(b)(i)]。

- EN 13631-3:2004。

- Council Regulation (EC) No 440/2008; A.14.

- GB/T 21566-2008。

- STANAG 4487。

- AOP 7 Ed. 2, 201.02.006。

- MIL-STD-1751A, Method 1024。

- US ARMY TB 700-2, Section 5-3d。

- EMTAP, Manual of Tests, Test No 44

-

The BAM Friction Apparatus FSKM 10 is designed to determine sensitivity to friction stimuli of tested substances in the wide range of frictional loads between 0.1 N and 360 N. The FSKM 10 has a robust stainless-steel frame and it is equipped with a unique interchangeable loading arm mechanism. Thanks to that mechanism, all types of energetic materials can be tested on this single device.

APPLICATIONSFriction between hard surfaces is one of the most frequent causes of accidental explosions. The friction sensitivity of a tested substance is determined in accordance with the standardized BAM procedure using this BAM Friction Apparatus FSKM 10.

ADVANTAGES & FEATURES

- Unique interchangeable loading arm concept

- Standard 6-position loading arm accompanied by two sets of weights generating loads between 0.5 N and 360 N

- Lightweight 3-position loading arm, specially designed for testing highly sensitive substances, accompanied by two sets of weights generating loads between 0.1 N and 98 N

- Protective shield to protect personnel against potential fragments of a porcelain plate or a peg

- Digitally controlled stepper motor for high precision movement of the porcelain plate carriage

- Working table with a stainless-steel frame covered by a conductive surface

- Variable speed of porcelain plate carriage between 20 and 300 RPM

- Safeguard

- Remote control

- Wide range of accessories

- Premium quality consumables at affordable prices

Porcelain plate carriage 6-position loading arm BAM 6A (dismantled) COMPLIANCE

- UN Recommendation on the Transport of Dangerous Goods, Manual of Tests and Criteria, [13.4.2 Test 3(b)(i)]。

- EN 13631-3:2004。

- Council Regulation (EC) No 440/2008; A.14.

- GB/T 21566-2008。

- STANAG 4487。

- AOP 7 Ed. 2, 201.02.006。

- MIL-STD-1751A, Method 1024。

- US ARMY TB 700-2, Section 5-3d。

- EMTAP, Manual of Tests, Test No 44