-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

Automatic Research

Automatic Research

-

AWSensors

AWSensors

-

BASI

BASI

-

BRS

BRS

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Cmc

Cmc

-

CTRL

CTRL

-

DANATRONICS

DANATRONICS

-

DV Power

DV Power

-

EA Technology

EA Technology

-

ECH

ECH

-

EL-CELL

EL-CELL

-

Electrothermal

Electrothermal

-

Elsys

Elsys

-

ELVEFLOW

ELVEFLOW

-

Enapter

Enapter

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Enervac

Enervac

-

FASTEC

FASTEC

-

Gaskatel

Gaskatel

-

GE

GE

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GMW

GMW

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HTW

HTW

-

HUBER

HUBER

-

HVPD

HVPD

-

Ida

Ida

-

Instytut Fotonowy

Instytut Fotonowy

-

IVIUM

IVIUM

-

Jacomex

Jacomex

-

Jenway

Jenway

-

JGG

JGG

-

KEHUA TECH

KEHUA TECH

-

Labdex

Labdex

-

Labnics

Labnics

-

LIQUID

LIQUID

-

METERTEST

METERTEST

-

Metrel

Metrel

-

Microrad

Microrad

-

micrux

micrux

-

ndb

ndb

-

Neware

Neware

-

Norecs

Norecs

-

Novocontrol

Novocontrol

-

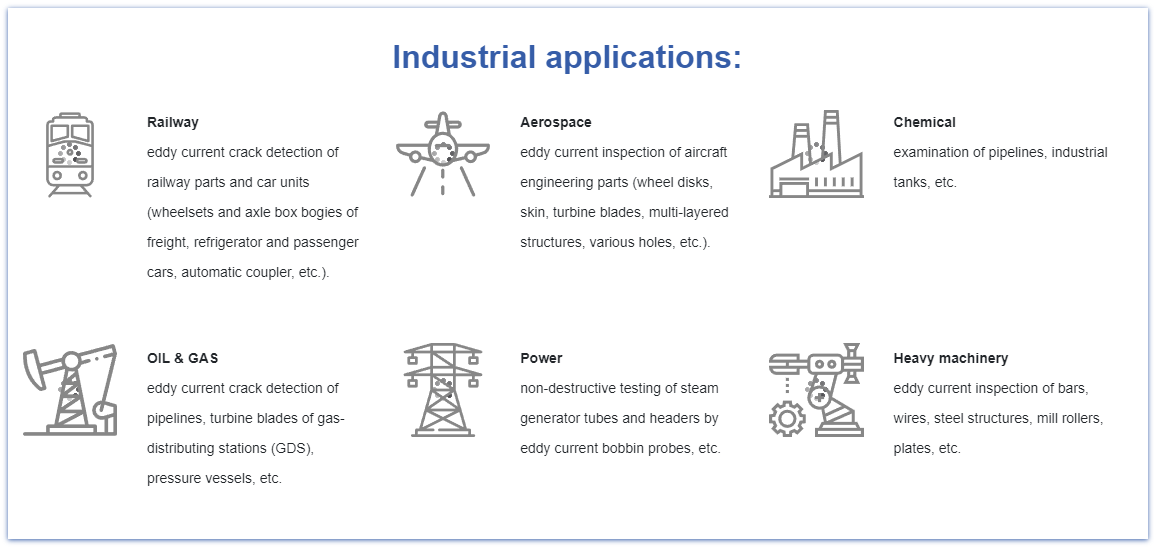

OKOndt Group

OKOndt Group

-

OZM

OZM

-

Pine Research

Pine Research

-

Redoxme

Redoxme

-

SATIR

SATIR

-

SDT

SDT

-

Serstech

Serstech

-

VacCoat

VacCoat

-

Zurich

Zurich

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- Automatic Research

- AWSensors

- BASI

- BRS

- CALMET

- CHECKLINE

- Cmc

- CTRL

- DANATRONICS

- DV Power

- EA Technology

- ECH

- EL-CELL

- Electrothermal

- Elsys

- ELVEFLOW

- Enapter

- ENERGY SUPPORT

- Enervac

- FASTEC

- Gaskatel

- GE

- GIUSSANI

- Globecore

- GMW

- GREENLIGHT

- GRZ

- HIGH SENSE SOLUTIONSHTW

- HTW

- HUBER

- HVPD

- Ida

- Instytut Fotonowy

- IVIUM

- Jacomex

- Jenway

- JGG

- KEHUA TECH

- Labdex

- Labnics

- LIQUID

- METERTEST

- Metrel

- Microrad

- micrux

- ndb

- Neware

- Norecs

- Novocontrol

- OKOndt Group

- OZM

- Pine Research

- Redoxme

- SATIR

- SDT

- Serstech

- VacCoat

- Zurich

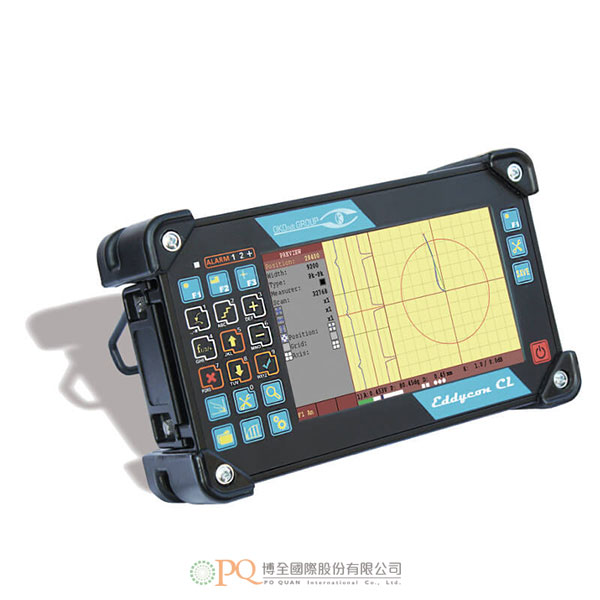

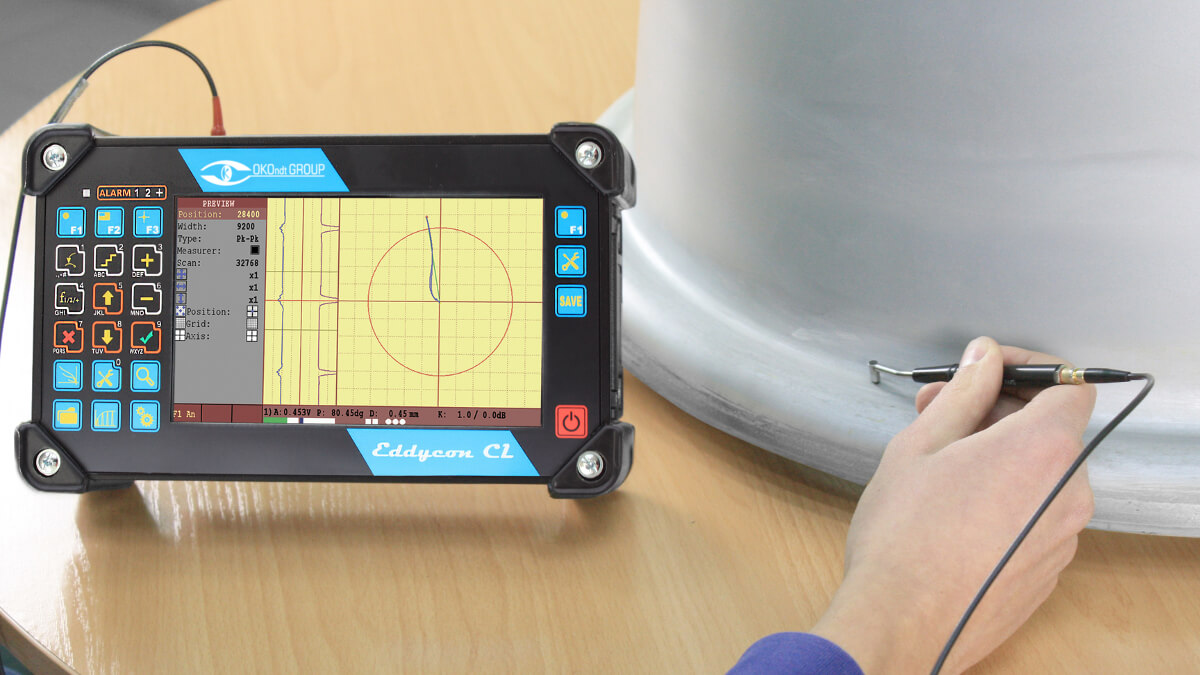

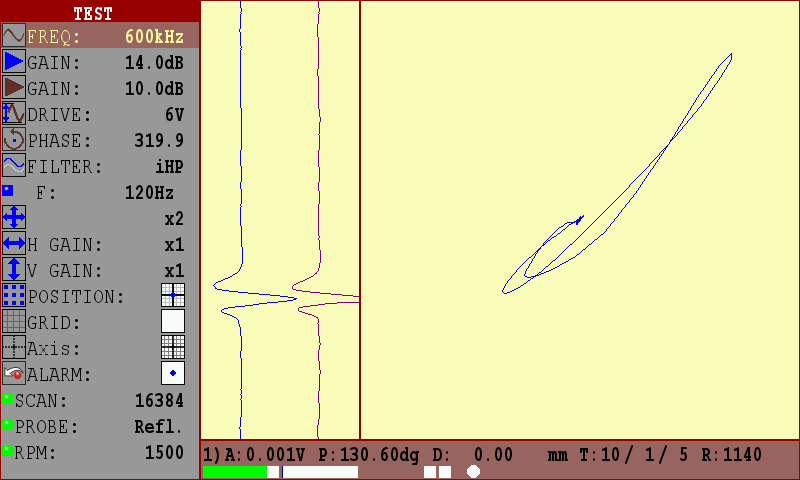

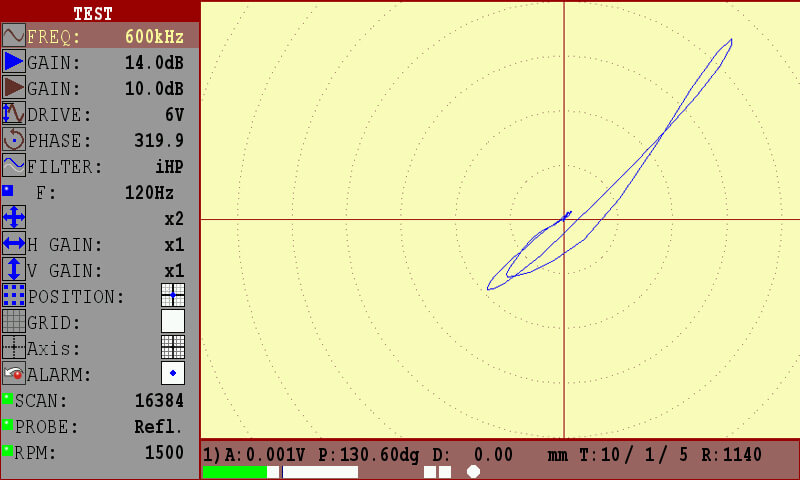

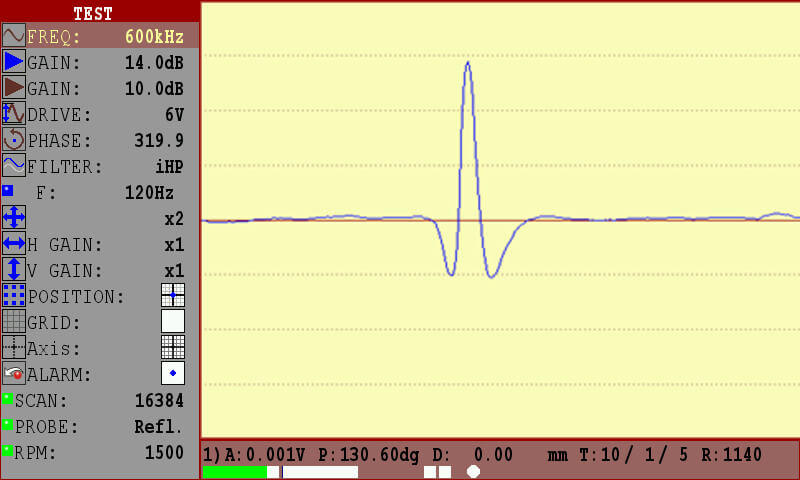

Eddycon CL Portable Eddy Current Flaw Detector

Portable Eddy Current Flaw Detector 型號:Eddycon CL-

The EDDYCON CL is a fully portable, rugged eddy current instrument, delivering an exceptional performance and highly reliable inspection results.

Intended Use

- detection of surface and near-surface defects;

- detection of subsurface defects (cracks, overlaps, holes, fine cracks, etc.) in non-ferrous conductive materials;

- inspection of bolt holes with rotary scanners;

- thickness measurement of paint coating;

- measurement of electrical conductivity and magnetic permeability;

- eddy current inspection of welding.

The Eddycon CL is ISO 15548 compliant.

The Eddycon CL allows full eddy current testing of aircraft parts according to the regulations of AIRBUS A318 / A319 / A320 / A321 NONDESTRUCTIVE TESTING MANUAL NTM, BOEING 737 NON-DESTRUCTIVE TEST MANUAL.

A fully portable instrument in solid housing

The Eddycon CL has a shockproof housing with rubber protective corners. The device can be utilized as a benchtop unit as well as a solution for harsh inspection environments. The Eddycon CL is furnished with a folding handle and a neck strap.

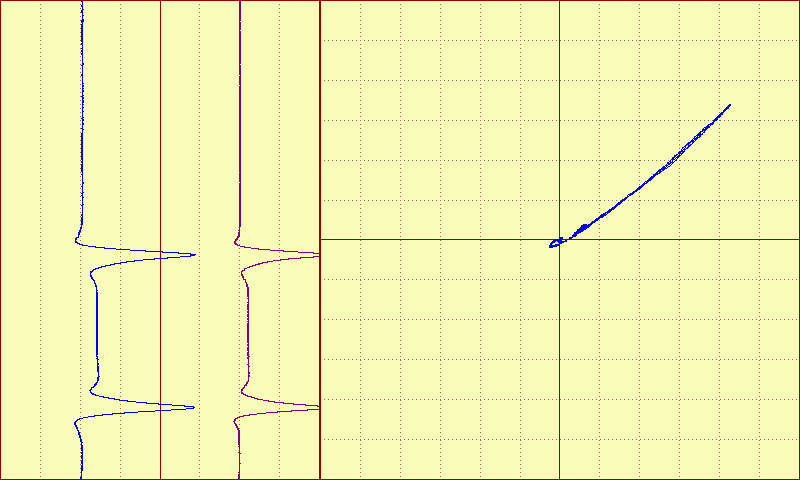

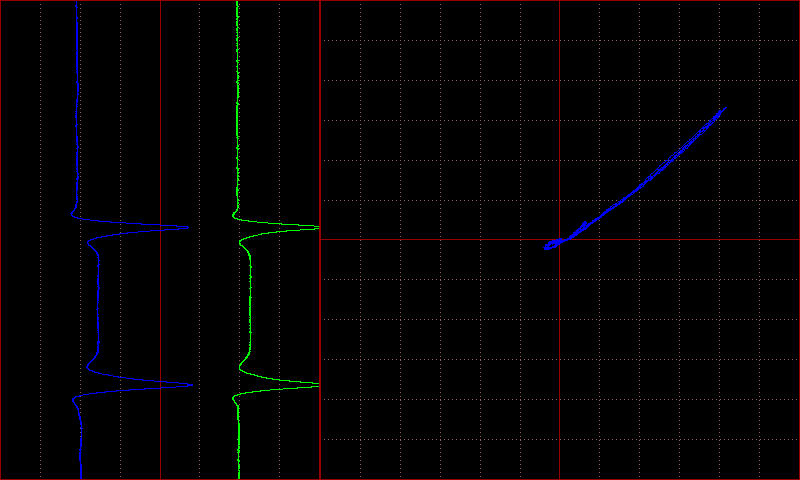

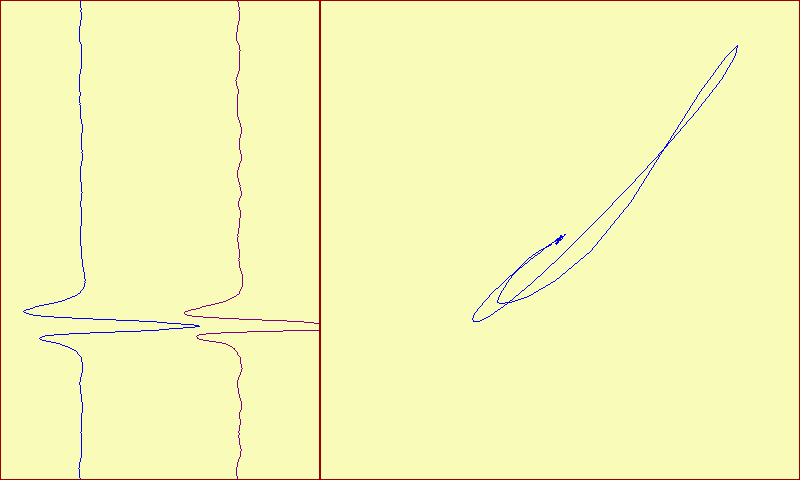

A large 7.2" TFT color display

A 800×480 pixel resolution display of the Eddycon CL ensures high visibility even from a distance and in any lighting conditions, which is of crucial importance for challenging inspections. The Eddycon CL screen has three display modes: light, dark, and standard.

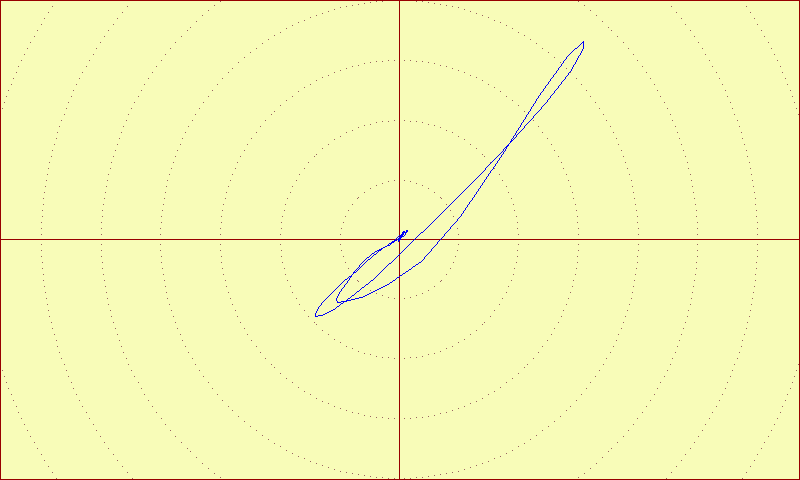

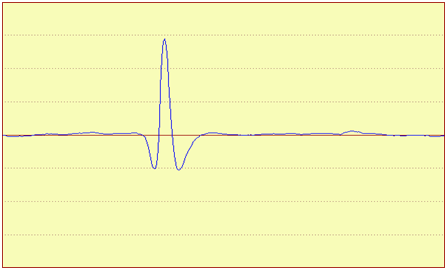

a) Menu+XY+A(t)

b) Menu+XY

c) Menu+A(t)

d) XY+A(t)

e) XY

f) A(t)Navigation

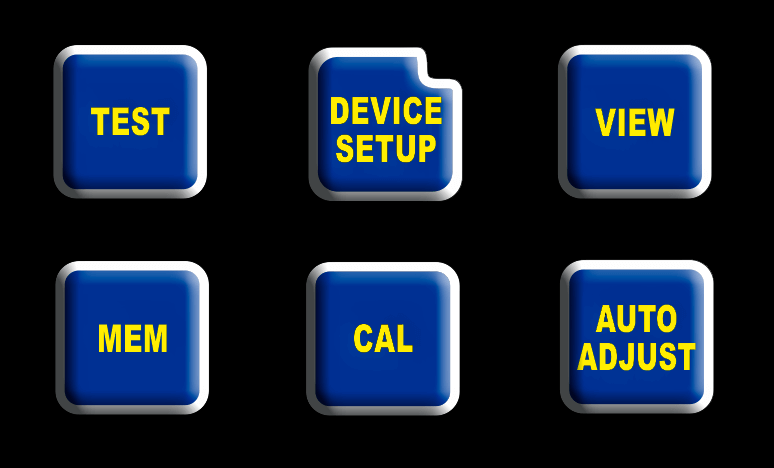

Elaborated keypad design gives a quick access to any menu of the flaw detector by pressing a single key only!TESTING menu - main operating mode of the flaw detector;

MEMORY menu - is used to save/download the settings and test results;

SETTINGS menu - basic settings of the flaw detector;

VIEW menu - allows viewing test results saved to the flaw detector’s memory;

CALIBRATION menu - serves to create calibration curves for more precise evaluation of flaw depth.