選擇品牌

-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

Automatic Research

Automatic Research

-

AWSensors

AWSensors

-

BASI

BASI

-

BRS

BRS

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Cmc

Cmc

-

C-Tech

C-Tech

-

CTRL

CTRL

-

DANATRONICS

DANATRONICS

-

DV Power

DV Power

-

EA Technology

EA Technology

-

ECH

ECH

-

EL-CELL

EL-CELL

-

Electrothermal

Electrothermal

-

Elsys

Elsys

-

ELVEFLOW

ELVEFLOW

-

Enapter

Enapter

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Enervac

Enervac

-

FASTEC

FASTEC

-

Gaskatel

Gaskatel

-

GE

GE

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GMW

GMW

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HTW

HTW

-

HUBER

HUBER

-

HVPD

HVPD

-

Ida

Ida

-

Instytut Fotonowy

Instytut Fotonowy

-

IVIUM

IVIUM

-

Jacomex

Jacomex

-

Jenway

Jenway

-

JGG

JGG

-

KEHUA TECH

KEHUA TECH

-

Labdex

Labdex

-

Labnics

Labnics

-

LIQUID

LIQUID

-

METERTEST

METERTEST

-

Metrel

Metrel

-

Microrad

Microrad

-

micrux

micrux

-

ndb

ndb

-

Neware

Neware

-

Norecs

Norecs

-

Novocontrol

Novocontrol

-

OKOndt Group

OKOndt Group

-

OZM

OZM

-

Pine Research

Pine Research

-

Redoxme

Redoxme

-

SATIR

SATIR

-

SDT

SDT

-

Serstech

Serstech

-

VacCoat

VacCoat

-

Zurich

Zurich

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- Automatic Research

- AWSensors

- BASI

- BRS

- CALMET

- CHECKLINE

- Cmc

- C-Tech

- CTRL

- DANATRONICS

- DV Power

- EA Technology

- ECH

- EL-CELL

- Electrothermal

- Elsys

- ELVEFLOW

- Enapter

- ENERGY SUPPORT

- Enervac

- FASTEC

- Gaskatel

- GE

- GIUSSANI

- Globecore

- GMW

- GREENLIGHT

- GRZ

- HIGH SENSE SOLUTIONSHTW

- HTW

- HUBER

- HVPD

- Ida

- Instytut Fotonowy

- IVIUM

- Jacomex

- Jenway

- JGG

- KEHUA TECH

- Labdex

- Labnics

- LIQUID

- METERTEST

- Metrel

- Microrad

- micrux

- ndb

- Neware

- Norecs

- Novocontrol

- OKOndt Group

- OZM

- Pine Research

- Redoxme

- SATIR

- SDT

- Serstech

- VacCoat

- Zurich

-

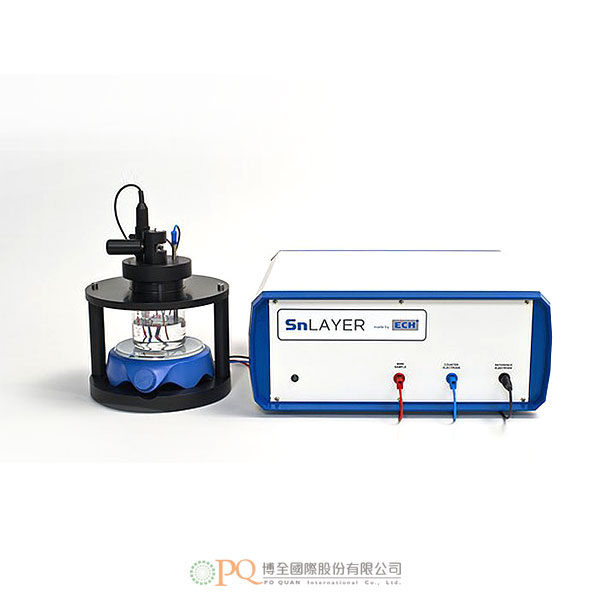

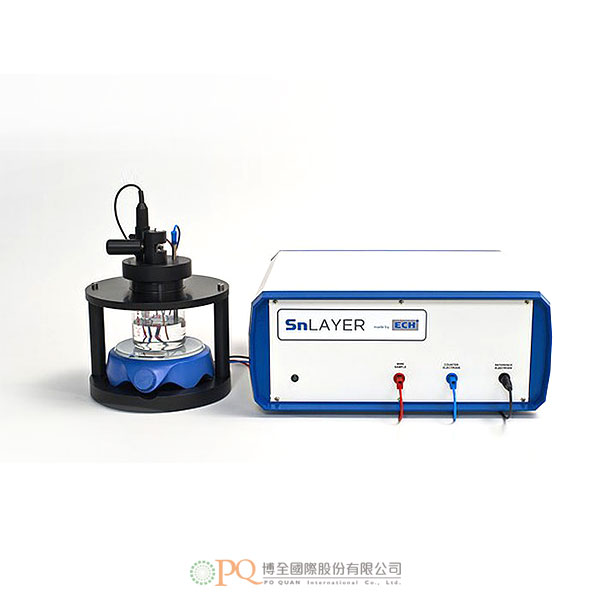

The thickness of the non-alloyed and alloyed tin layer on thin copper wires can be measured with high accuracy in a short duration by the electrochemical Analyzer SnLayer.

The coulometric determination of the thickness of the tin layer at the copper wires based on a newly developed procedure: the technique of voltammetry with a multiple potential-ramp.

The total amount of tin as well as the non-alloyed and the alloyed tin-part is detectable in only one measurement.

Applications

- Determination of thickness of tin at copper wires

- Determination of the non-alloyed and alloyed tin layer

- Conductor board manufacture

- Wire and cable manufacture

- Quality management in rolling mills

- Application in metal industry

Advantages

- Complete measurement system for the layer thickness of tin

- Differentiation of non-alloyed and alloyed tin

- Fast analysis

- Typical duration: 8 min (non-alloyed and alloyed tin) < 2 min (non-alloyed tin)

- According to the actual standard regulations

- Automatic procedures

- Customer-friendly handling

- Pre-defined methods for selected wire-types

- Generation of individual methods

- Intuitive software

- Comprehensive statistic module

- Wide dynamic range for various wire-diameters and layer thickness

- High precision of the analysis

-

Working electrode: Sample wire Reference electrode: Ag/AgCl Counter electrode: Pt Typical duration: 2 … 8 Min (depending on the sample) Typical wire diameters: 0.05 … 8 mm Typical layer thickness: 0.01 … 22 µm Power supply: 230 V/50 Hz, 115 V/60 Hz Power input: 150 W Dimensions of control unit: 370 x 345 x 160 mm (L x D x H) Dimensions of titration unit: Max. 200 x 300 mm (Ø x H) Weight: 1 kg Device control: PC software (PC not included in the scope of delivery)