選擇品牌

-

Neware

Neware

-

Pine Research

Pine Research

-

OKOndt Group

OKOndt Group

-

Novocontrol

Novocontrol

-

Norecs

Norecs

-

METERTEST

METERTEST

-

Microrad

Microrad

-

Metrel

Metrel

-

Labdex

Labdex

-

SDT

SDT

-

micrux

micrux

-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

AWSensors

AWSensors

-

Automatic Research

Automatic Research

-

BASI

BASI

-

BRS

BRS

-

Cmc

Cmc

-

CTRL

CTRL

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

C-Tech

C-Tech

-

DV Power

DV Power

-

DANATRONICS

DANATRONICS

-

ECH

ECH

-

Elsys

Elsys

-

Enervac

Enervac

-

Enapter

Enapter

-

ELVEFLOW

ELVEFLOW

-

EA Technology

EA Technology

-

EL-CELL

EL-CELL

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Electrothermal

Electrothermal

-

FASTEC

FASTEC

-

GE

GE

-

GMW

GMW

-

Gaskatel

Gaskatel

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HTW

HTW

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HUBER

HUBER

-

Labnics

Labnics

-

Ida

Ida

-

LIQUID

LIQUID

-

Instytut Fotonowy

Instytut Fotonowy

-

KEHUA TECH

KEHUA TECH

-

JGG

JGG

-

HVPD

HVPD

-

Jenway

Jenway

-

Jacomex

Jacomex

-

IVIUM

IVIUM

-

ndb

ndb

-

OZM

OZM

-

Redoxme

Redoxme

-

Serstech

Serstech

-

SATIR

SATIR

-

VacCoat

VacCoat

-

Zurich

Zurich

- Neware

- Pine Research

- OKOndt Group

- Novocontrol

- Norecs

- METERTEST

- Microrad

- Metrel

- Labdex

- SDT

- micrux

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- AWSensors

- Automatic Research

- BASI

- BRS

- Cmc

- CTRL

- CALMET

- CHECKLINE

- C-Tech

- DV Power

- DANATRONICS

- ECH

- Elsys

- Enervac

- Enapter

- ELVEFLOW

- EA Technology

- EL-CELL

- ENERGY SUPPORT

- Electrothermal

- FASTEC

- GE

- GMW

- Gaskatel

- GIUSSANI

- Globecore

- GREENLIGHT

- GRZ

- HTW

- HIGH SENSE SOLUTIONSHTW

- HUBER

- Labnics

- Ida

- LIQUID

- Instytut Fotonowy

- KEHUA TECH

- JGG

- HVPD

- Jenway

- Jacomex

- IVIUM

- ndb

- OZM

- Redoxme

- Serstech

- SATIR

- VacCoat

- Zurich

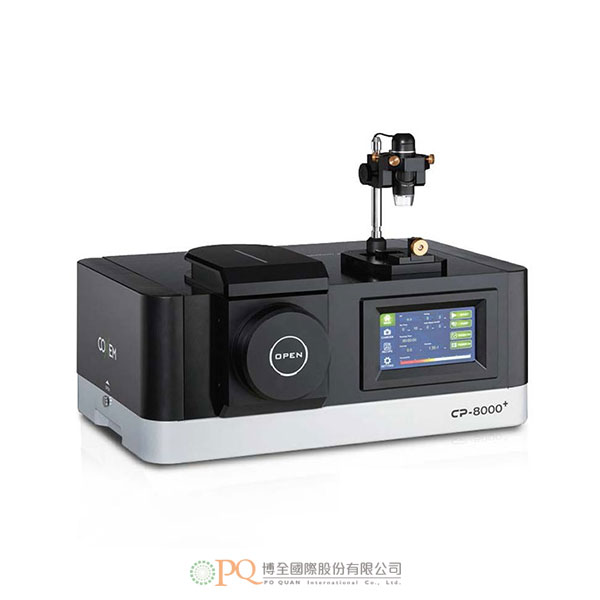

截面拋光機

Ion Beam Polisher 型號:CP-8000+

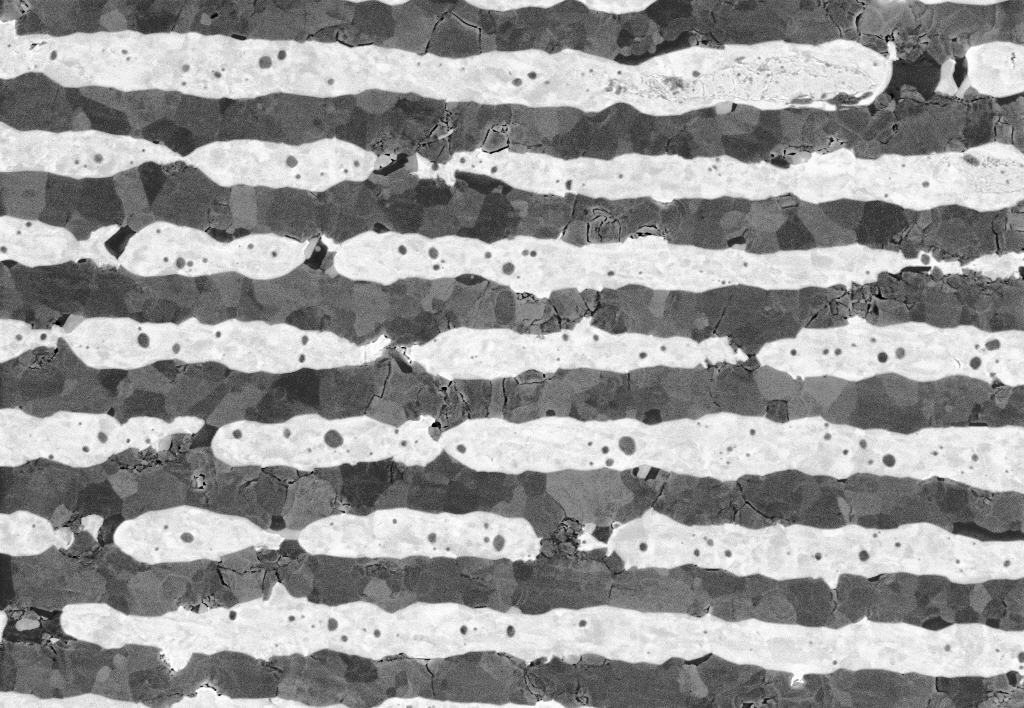

CP-8000+ 是一種先進的樣品製備工具,可利用氬離子束蝕刻樣品的橫截面。 此過程可避免物理變形和結構損壞,而無需複雜的化學過程。 此外,該系統還能處理從幾十㎛到幾mm㎛的大面積樣品,從而簡化了樣品的橫斷面分析。

-

CP-8000+ 是一種先進的樣品製備工具,可利用氬離子束蝕刻樣品的橫截面。 此過程可避免物理變形和結構損壞,而無需複雜的化學過程。 此外,該系統還能處理從幾十㎛到幾mm的大面積樣品,從而簡化了樣品的橫斷面分析。

應用

-

使用的氣體 氬氣 銑削速度 700 μm/h (Si at 8kV) 加速電壓 2~8 kV 光束直徑 Approx. 500 μm 操作壓力 4.3 x 10-5 torr 光束對準 使用數位顯微鏡進行精密光束對準 最大樣品尺寸 20(W) x 10(D) x 9(H)mm 樣品移動範圍 (Z: ±2mm, Y: ±2mm) 旋轉 -35° ~ +35° 平面銑削台 傾斜範圍:40° 至 80°

旋轉速度:6 rpm/min

樣品尺寸 : 直徑 30 x 11.4 mm顯示器 觸控面板(1024 x 600 7 吋顯示器) 腔室攝影機 放大倍率:x5、x10、x20、x40

4 階亮度控制

離子束觀察模式用於樣品對準的數位相機 放大倍率:x5、x10、x20、x40

USB 形式抽空系統 渦輪分子幫浦(66 公升/秒)+ 隔膜泵 尺寸 610(W) x 472(D) x 415(H)mm -

The CP-8000+ is an advanced sample preparation tool that etches a cross section of a sample using an argon ion beam. This process avoids physical deformation and structural damage, without requiring complicated chemical processes. In addition, the system simplifies cross-sectional analysis of the sample by processing large areas from tens of um to several mm.

application

-

Gas Used Ar(Argon) gas Milling Speed 700 μm/h (Si at 8kV) Accelerating Voltage 2~8 kV Beam Diameter Approx. 500 μm Working Pressure 4.3 x 10-5 torr Beam Alignment Precision beam alignment

using Digital MicroscopeMaximum Sample Size 20(W) x 10(D) x 9(H)mm Sample Moving Range (Z: ±2mm, Y: ±2mm) Rotation -35° ~ +35° Stage for Flat Milling Tilt Range : 40° to 80°

Rotation Speed : 6 rpm/min

Sample Size : Ø30 x 11.4mmDisplay Touch panel (1024 x 600 7 inch display) Chamber Camera Magnification : x5, x10, x20, x40

4 step brightness control

Ion beam observation modeDigital Camera for sample alignment Magnification : x5, x10, x20, x40

USB typeEvacuation System Turbo-molecular pump (66L/s)

+ Diaphragm pumpDimension 610(W) x 472(D) x 415(H)mm