-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

Automatic Research

Automatic Research

-

AWSensors

AWSensors

-

BASI

BASI

-

BRS

BRS

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

Cmc

Cmc

-

C-Tech

C-Tech

-

CTRL

CTRL

-

DANATRONICS

DANATRONICS

-

DV Power

DV Power

-

EA Technology

EA Technology

-

ECH

ECH

-

EL-CELL

EL-CELL

-

Electrothermal

Electrothermal

-

Elsys

Elsys

-

ELVEFLOW

ELVEFLOW

-

Enapter

Enapter

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Enervac

Enervac

-

FASTEC

FASTEC

-

Gaskatel

Gaskatel

-

GE

GE

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GMW

GMW

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HTW

HTW

-

HUBER

HUBER

-

HVPD

HVPD

-

Ida

Ida

-

Instytut Fotonowy

Instytut Fotonowy

-

IVIUM

IVIUM

-

Jacomex

Jacomex

-

Jenway

Jenway

-

JGG

JGG

-

KEHUA TECH

KEHUA TECH

-

Labdex

Labdex

-

Labnics

Labnics

-

LIQUID

LIQUID

-

METERTEST

METERTEST

-

Metrel

Metrel

-

Microrad

Microrad

-

micrux

micrux

-

ndb

ndb

-

Neware

Neware

-

Norecs

Norecs

-

Novocontrol

Novocontrol

-

OKOndt Group

OKOndt Group

-

OZM

OZM

-

Pine Research

Pine Research

-

Redoxme

Redoxme

-

SATIR

SATIR

-

SDT

SDT

-

Serstech

Serstech

-

VacCoat

VacCoat

-

Zurich

Zurich

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- Automatic Research

- AWSensors

- BASI

- BRS

- CALMET

- CHECKLINE

- Cmc

- C-Tech

- CTRL

- DANATRONICS

- DV Power

- EA Technology

- ECH

- EL-CELL

- Electrothermal

- Elsys

- ELVEFLOW

- Enapter

- ENERGY SUPPORT

- Enervac

- FASTEC

- Gaskatel

- GE

- GIUSSANI

- Globecore

- GMW

- GREENLIGHT

- GRZ

- HIGH SENSE SOLUTIONSHTW

- HTW

- HUBER

- HVPD

- Ida

- Instytut Fotonowy

- IVIUM

- Jacomex

- Jenway

- JGG

- KEHUA TECH

- Labdex

- Labnics

- LIQUID

- METERTEST

- Metrel

- Microrad

- micrux

- ndb

- Neware

- Norecs

- Novocontrol

- OKOndt Group

- OZM

- Pine Research

- Redoxme

- SATIR

- SDT

- Serstech

- VacCoat

- Zurich

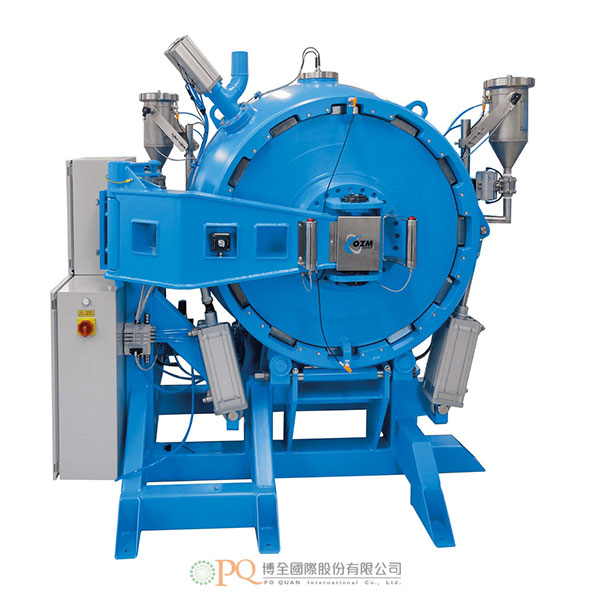

粉塵和氣體爆炸室

Dust and Gas Explosion Chambers 型號:CA 20L / CA 1M3-

爆炸室用於測量易燃粉塵、氣體、蒸氣和混合混合物的爆炸特性,如最大爆炸壓力、最大壓力上升率、爆炸下限和上限以及極限氧氣濃度。用於測試粉塵爆炸的爆炸室有兩種標準尺寸 - 20 公升(CA 20L™)和 1 m3(我們的 CA 1M3™)。通常用於氣體和蒸氣的爆炸室必須大於 5 公升,因此建議使用CA 20L爆炸室。

應用使用爆炸室的測試方法是認證機構、大學和其它研究機構用來確定粉塵、氣體和蒸汽危險特性的一套標準測試方法的重要組成部分。從這些測試中獲得的資訊對於設計緩解和保護措施(如爆炸通風裝置、自動化抑制或部分惰性化)至關重要。

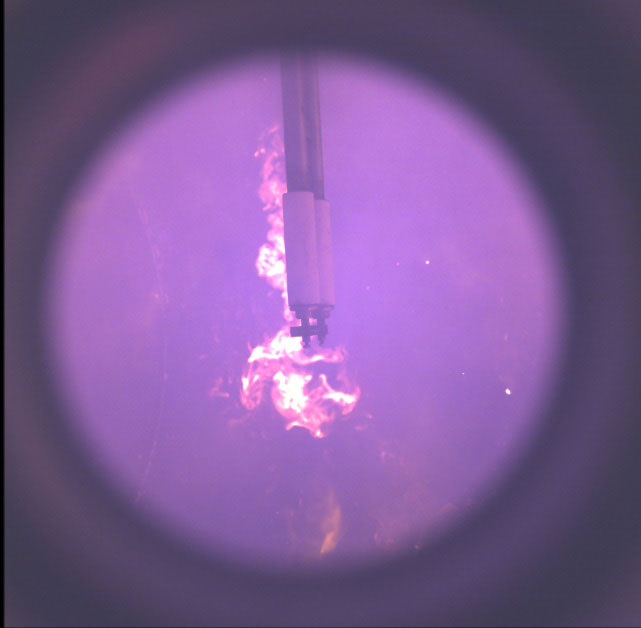

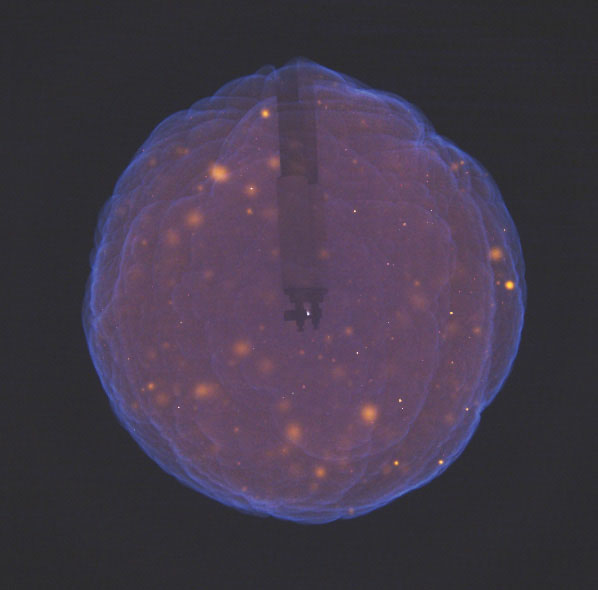

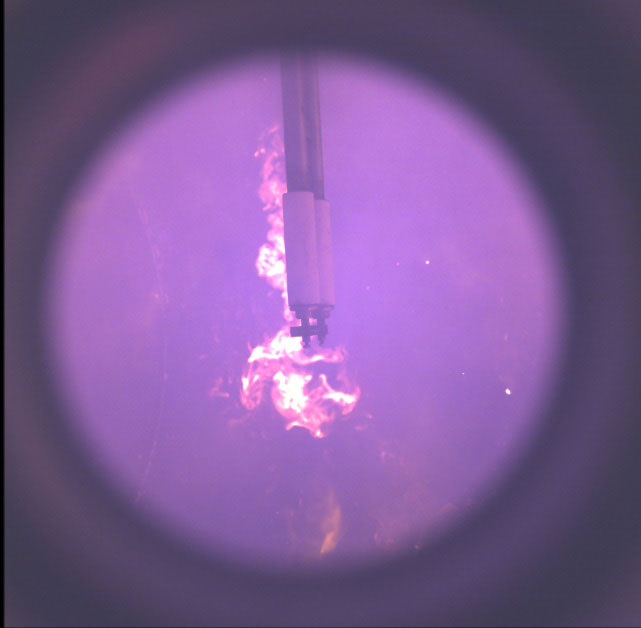

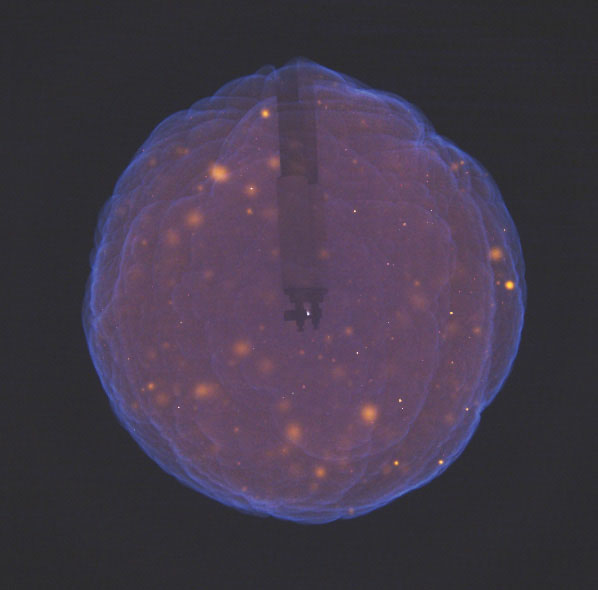

在空氣中甲烷含量為 9.5%時,火焰向下蔓延 空氣中所燃燒 9.5% 的甲烷

優勢和特點- 手動或全自動操作。

- 設計堅固,工作壓力最高可達 30 bar,經測試證明最高可達 40 bar。

- 三種點火系統:化學點火器、最大 10 J 的可調電容火花和可調節的持久火花。

- 氣體樣品劑量的自動程式。

- 大開口的腔體,可方便清潔腔室。

- K 型熱電偶嵌入腔體內。

- 在 1 m3的艙室內嵌入兩個分散系統。

- 用於測量火焰光強度的光學探頭。

- 可選配用在高達 200 °C 的初始溫度下運作。

- 適用於測量混合物混合爆炸的儀器。

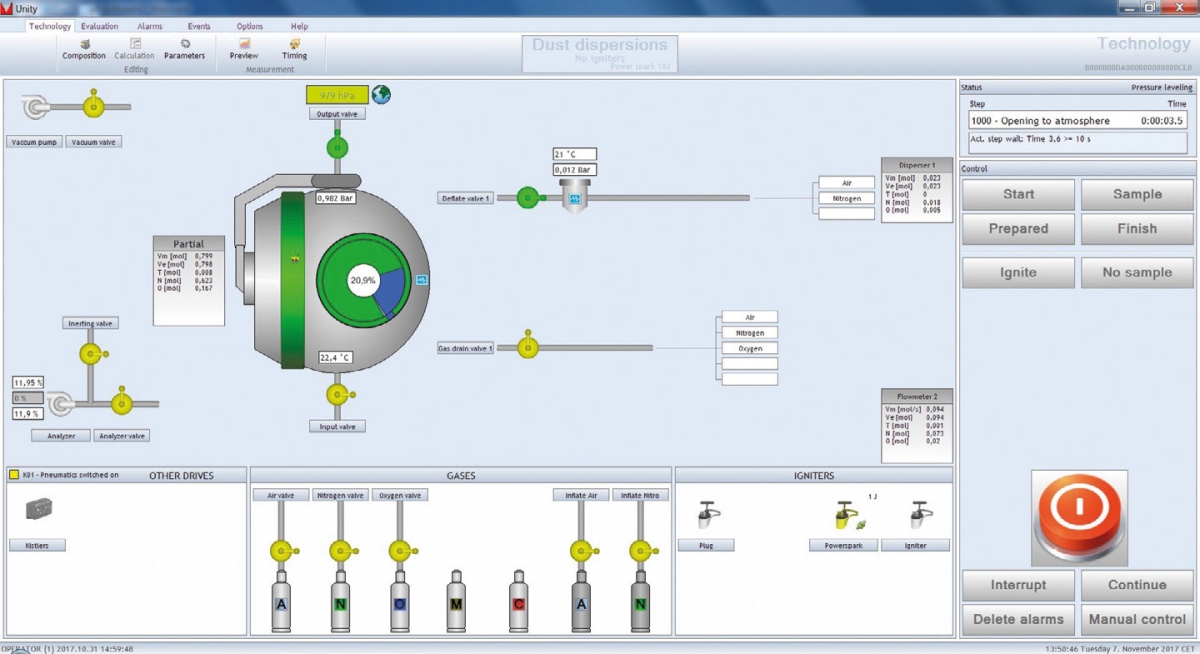

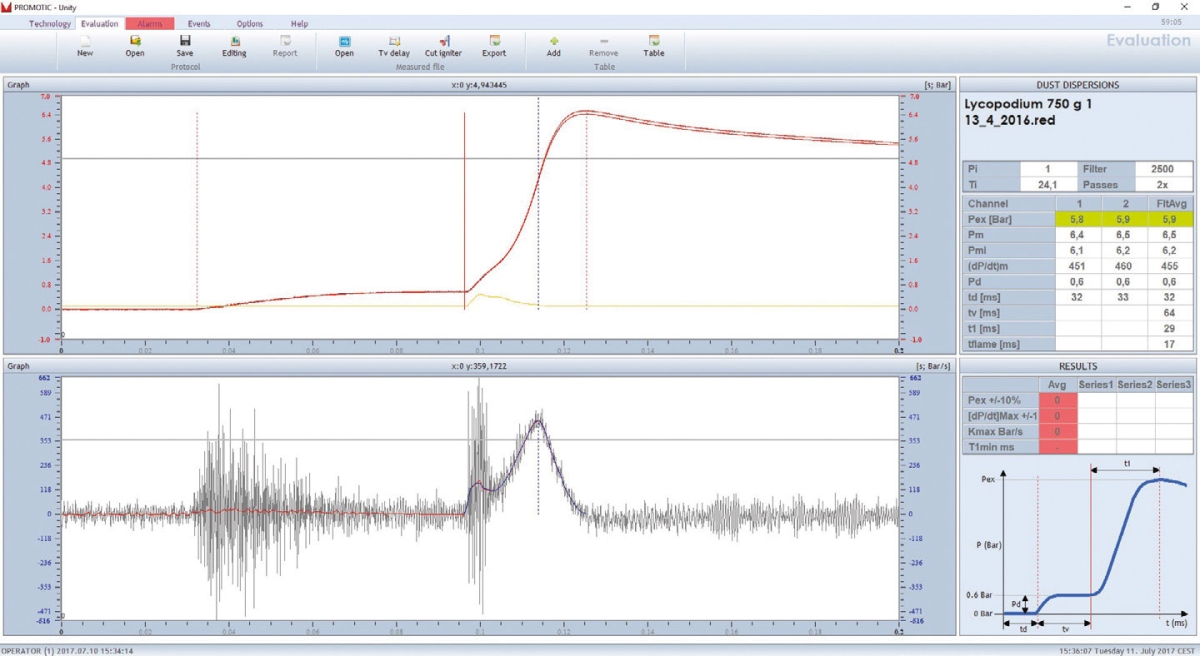

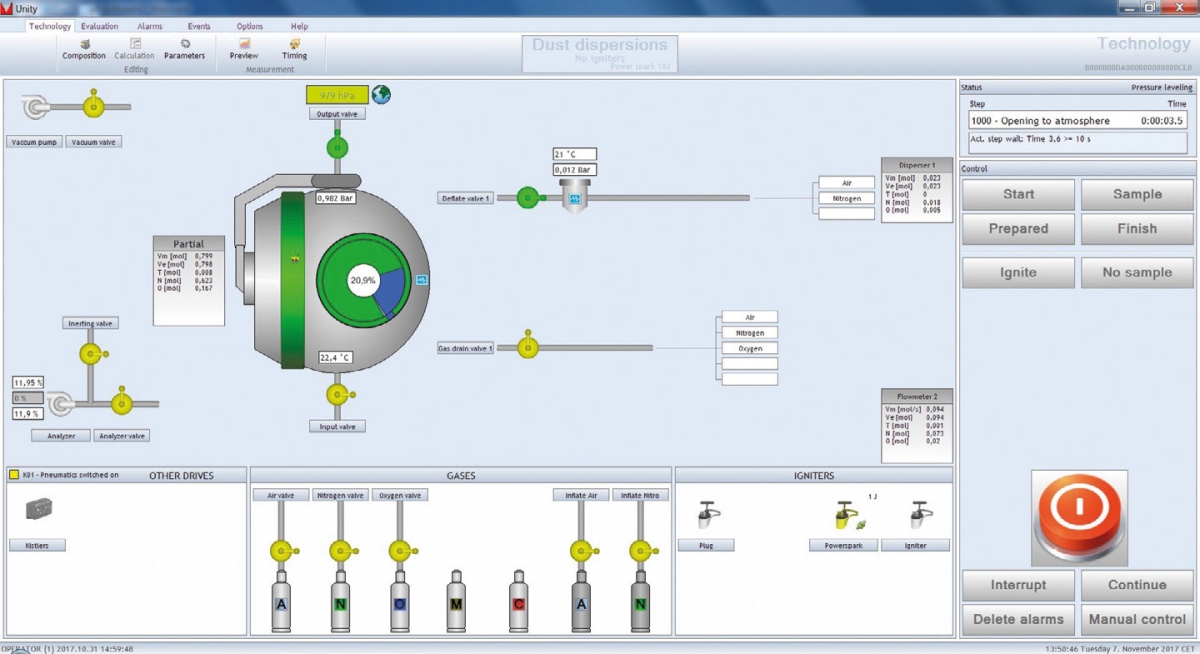

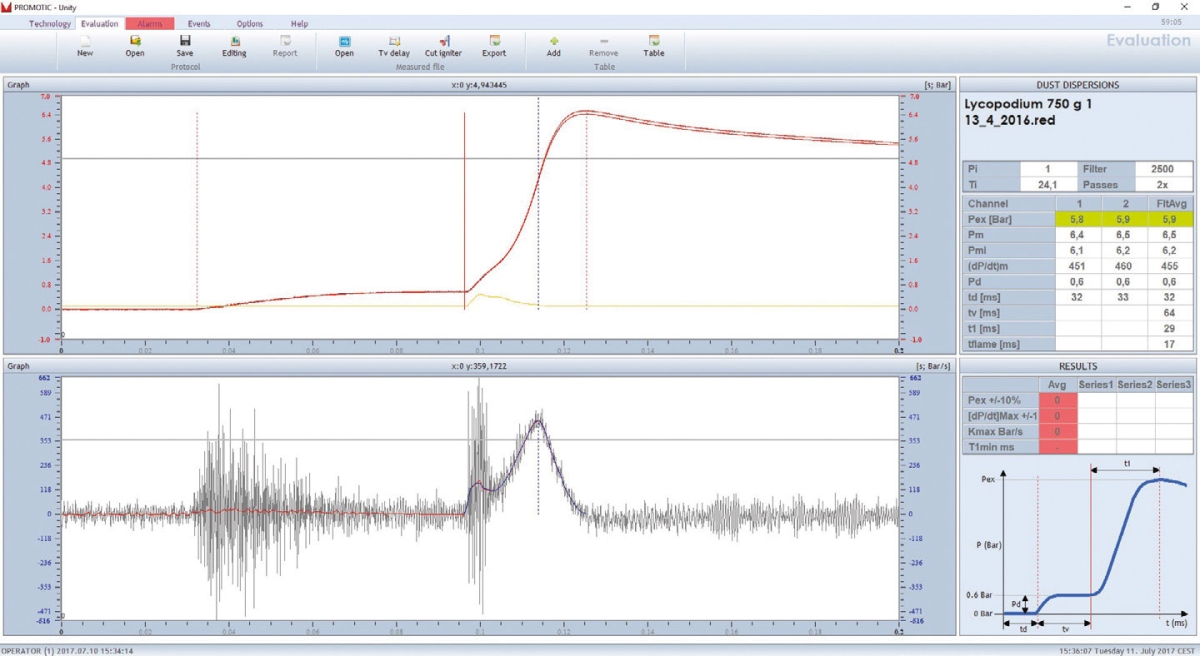

用於監測和/或控制測試裝置的軟體視窗 評估測得壓力-時間曲線(上視窗)和

dp/dt 時間圖(下視窗)

合規- EN 14034 (1-4)

- VDI 2263

- ISO/IEC 80079-20-2:Part 20-2

- ASTM E1226

- ASTM E1515

- EN 15967

- EN 14756

- EN 1839

-

Explosion chambers are used for measurement of explosion characteristics of flammable dusts, gases, vapors and hybrid mixtures, such as maximum explosion pressure, maximum rate of pressure rise, lower and upper explosibility limits and limiting oxygen concentration. There are two standardized sizes of the explosion chambers for testing dust explosions – 20 liters (our CA 20L™) and 1 m3 (our CA 1M3™). The explosion chamber for gases and vapors has to be larger than 5 liters, so our CA 20L is recommended for this purpose.

APPLICATIONS

Testing methods using the explosion chambers are an essential part of a standard set of tests used by certified bodies, universities and other research organizations to characterize the hazard properties of dusts, gases and vapors. The information received from these tests is critical for design of mitigating and protective measures, such as explosion venting devices, automatic suppression or partial inertization.

Downward spreading of the flame for 9.5 %

by vol. of methane in airAfterburning of 9.5 % by vol. of methane in air ADVANTAGES & FEATURES

- Manual or fully automatic operation

- Robust design with working pressure up to 30 bar, test proofed up to 40 bar f Three types of ignition systems: chemical igniter, adjustable capacitive spark up to 10 J and adjustable permanent spark

- Automatic procedure for dosage of gas samples

- Large opening for easy cleaning of the chambers

- K-type thermocouple embedded in the chamber

- Two dispersion systems embedded in 1 m3 chamber

- Optical probe for flame light intensity measurement

- Optionally equipped for operation with elevated initial temperatures up to 200 °C f Instrumentation suitable for measurements of hybrid mixture explosions

Technological window used for monitoring and/or

control of test setupEvaluation of measured pressure-time curve

(upper window) and dp/dt-time plot (lower window)COMPLIANCE

- EN 14034 (1-4)

- VDI 2263

- ISO/IEC 80079-20-2:Part 20-2

- ASTM E1226

- ASTM E1515

- EN 15967

- EN 14756

- EN 1839