-

Neware

Neware

-

Pine Research

Pine Research

-

OKOndt Group

OKOndt Group

-

Novocontrol

Novocontrol

-

Norecs

Norecs

-

METERTEST

METERTEST

-

Microrad

Microrad

-

Metrel

Metrel

-

Labdex

Labdex

-

SDT

SDT

-

micrux

micrux

-

AARONIA AG

AARONIA AG

-

ADASH

ADASH

-

Amptek

Amptek

-

AOiP

AOiP

-

AstroNova

AstroNova

-

AWSensors

AWSensors

-

Automatic Research

Automatic Research

-

BASI

BASI

-

BRS

BRS

-

Cmc

Cmc

-

CTRL

CTRL

-

CALMET

CALMET

-

CHECKLINE

CHECKLINE

-

C-Tech

C-Tech

-

DV Power

DV Power

-

DANATRONICS

DANATRONICS

-

ECH

ECH

-

Elsys

Elsys

-

Enervac

Enervac

-

Enapter

Enapter

-

ELVEFLOW

ELVEFLOW

-

EA Technology

EA Technology

-

EL-CELL

EL-CELL

-

ENERGY SUPPORT

ENERGY SUPPORT

-

Electrothermal

Electrothermal

-

FASTEC

FASTEC

-

GE

GE

-

GMW

GMW

-

Gaskatel

Gaskatel

-

GIUSSANI

GIUSSANI

-

Globecore

Globecore

-

GREENLIGHT

GREENLIGHT

-

GRZ

GRZ

-

HTW

HTW

-

HIGH SENSE SOLUTIONSHTW

HIGH SENSE SOLUTIONSHTW

-

HUBER

HUBER

-

Labnics

Labnics

-

Ida

Ida

-

LIQUID

LIQUID

-

Instytut Fotonowy

Instytut Fotonowy

-

KEHUA TECH

KEHUA TECH

-

JGG

JGG

-

HVPD

HVPD

-

Jenway

Jenway

-

Jacomex

Jacomex

-

IVIUM

IVIUM

-

ndb

ndb

-

OZM

OZM

-

Redoxme

Redoxme

-

Serstech

Serstech

-

SATIR

SATIR

-

VacCoat

VacCoat

-

Zurich

Zurich

- Neware

- Pine Research

- OKOndt Group

- Novocontrol

- Norecs

- METERTEST

- Microrad

- Metrel

- Labdex

- SDT

- micrux

- AARONIA AG

- ADASH

- Amptek

- AOiP

- AstroNova

- AWSensors

- Automatic Research

- BASI

- BRS

- Cmc

- CTRL

- CALMET

- CHECKLINE

- C-Tech

- DV Power

- DANATRONICS

- ECH

- Elsys

- Enervac

- Enapter

- ELVEFLOW

- EA Technology

- EL-CELL

- ENERGY SUPPORT

- Electrothermal

- FASTEC

- GE

- GMW

- Gaskatel

- GIUSSANI

- Globecore

- GREENLIGHT

- GRZ

- HTW

- HIGH SENSE SOLUTIONSHTW

- HUBER

- Labnics

- Ida

- LIQUID

- Instytut Fotonowy

- KEHUA TECH

- JGG

- HVPD

- Jenway

- Jacomex

- IVIUM

- ndb

- OZM

- Redoxme

- Serstech

- SATIR

- VacCoat

- Zurich

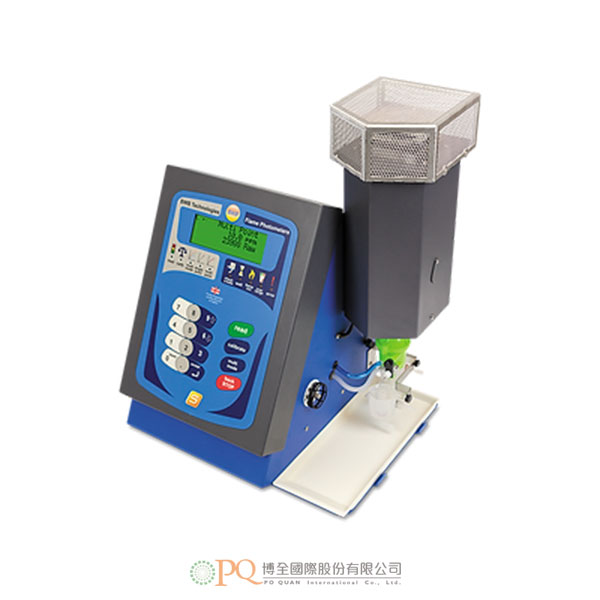

Sugar 火焰光度計

BWB Sugar Flame Photometer 型號:Sugar-

鉀和鈉檢測現在已可以進行全天候的在線檢測,具有獨特配置的檢測通道,可在鉀控制範圍內實現極高的準確性。

透過專有的 BWB 光學陣列檢測系統進行具體調整和優化,這項制勝公式使得該系統可以在單通道檢測中精確的量測Na與K。

這款特殊的火焰光度計是為全球糖生產市場需求和設計的。

幾十年來,有一些傳統的火焰光度計製造商一直服務於這個市場,但現在這些曾經強大而出色的設備即將停產。

BWB SUGAR 火焰光度計是具有專門的鉀和鈉通道的檢測功能,並提供針對鉀和鈉的混合特定需求的多點校準解決方案。

此外,根據客戶的要求,我們的Collection Cup為我們的混合室/檢測系統提供實時的樣品檢視,“Collection Cup”系統還提供約5 毫升/分鐘的進料方式,並且僅要求樣品與環境溫度相近即可。

FP/PC APP

這種完全獨特的 BWB 功能允許透過內部網路或互聯網連結共享多個安裝詳細信息,從而透過單一中控室提供“分散式控制”,工作人員完全遠離煉油廠現場本身。對於在世界各地擁有多個站點的大型糖業公司來說,這使得可以從世界任何地方的集中位置獲取專業知識,並即時進行幾乎無限的數據累積和分析。

可輸出.csv 檔案格式,可讓使用者建立新穎且專有的 Excel 電子表格並快速有效地共享資料。

產品特點:- 獨特的混合 BWB 雙通道,專注於高精度鉀和鈉測量。

- 可用“IRS”(內部參考標準)。

- 支援4-20mA 兩線輸出相容SCADA軟體。

- 支援即時線上監控系統。

- 使用專有的 BWB 收集杯提供恆定的冷凝流。

- 內置空氣壓縮機;由 BWB於 2007 年首創,現已在全球現場使用超過 1000 台設備得到驗證。

- 含括基本儀器所需器具,可協助您入門。

- 使用者可選擇小數位。

- 直覺的使用者介面真正易於使用。

- 顯示提示引導操作。

- 透過 PC 連結與 BWB 的 FP-PC 應用程式共享數據。

-

Sample rate

2 – 3.5ml/min

Tubing materials

Silicone and Tygon®

Required desk space for Instrument

50cm (H) x 45cm (W) x 45cm (D)

*For Safety reasons the Flame photometer requires 1m of

unobstructed space above to allow dissipation of heat from the chimney.Instrument size

Sugar Flame Photometer

51cm (H) x 39cm (W) x 35cm (D)

(20in x 15in x 14in)Shipping

65cm (H) x 49cm (W) x 43cm (D)

(25in x 19in x 17in)Weight

Sugar Flame Photometer – 14kg (30.8lbs)

Shipping – 25kg (55.1lbs)

Power requirements

100V – 250V AC at 50 or 60Hz

automatically selectingReadout

LCD, four line, alpha numeric, back lit.

Optimal range

Single point calibration

Na 0.1 – 60ppm

K 0.05 – 100ppm

Multi Point Calibration

Na 0.1 – 1000ppm

K 0.05 – 1000ppm

Reproducibility

<1% Coefficient of variability for 20

consecutive samples over ten minutes at

concentrations of 100ppm or less.

(After instrument stabilisation).Specificity

Na/K/Li = <1% to each other when

equal in concentration at <100ppmLimit of detection (LOD) and

limit of quantification (LOQ)LOD LOQ

Na – 0.03ppm Na – 0.1ppm

K – 0.02ppm K – 0.05ppm

Time to stability

Less than 15 seconds after sample is

introduced into the flameIons measured

Potassium

SodiumInterfaces

USB

4-20mA output capable of direct link to SCADA systems

Optional integrated printer

.CSV and .PDF generated reports and files via FP-PC software

Collection Cup providing 24/7 live automated sampling*

Recommended minimum warm up

time based on ambient temperature21ºC – 25 minutes

Fuel requirement

Propane, Butane or Natural Gas*

regulated to 19Bar. Flow rate of O.4l/min*with modifications. BWB Technologies

recommends either Propane or Butane

for optimum results. -

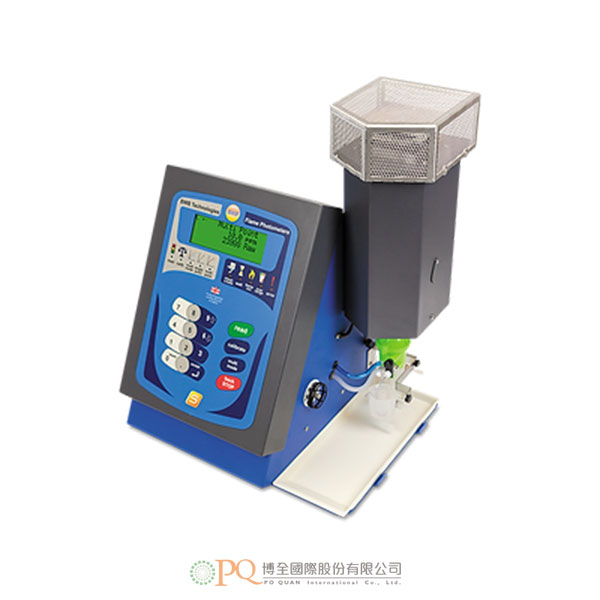

- Uniquely hybridized BWB dual channel, focused for high accuracy potassium and sodium measurements

- “IRS” (Internal Reference Standard) available

- 4-20mA 2-wire output compatible with SCADA software

- Live online monitoring

- Constant condensation stream feeds with use of the proprietary BWB collection cup

- Built-in air compressor; pioneered by BWB technologies in 2007 and proven now with over 1000 units in global field use

- Solutions and labware included; “Just Add Gas”, the hallmark of the user friendly BWB flame photometer (FES) program

- User selectable decimal places

- Intuitive user interface for true ease of use

- Display prompts step by step operation

- Data sharing via PC link with BWB’s FP-PC app

-

Sample rate

2 – 3.5ml/min

Tubing materials

Silicone and Tygon®

Required desk space for Instrument

50cm (H) x 45cm (W) x 45cm (D)

*For Safety reasons the Flame photometer requires 1m of

unobstructed space above to allow dissipation of heat from the chimney.Instrument size

Sugar Flame Photometer

51cm (H) x 39cm (W) x 35cm (D)

(20in x 15in x 14in)Shipping

65cm (H) x 49cm (W) x 43cm (D)

(25in x 19in x 17in)Weight

Sugar Flame Photometer – 14kg (30.8lbs)

Shipping – 25kg (55.1lbs)

Power requirements

100V – 250V AC at 50 or 60Hz

automatically selectingReadout

LCD, four line, alpha numeric, back lit.

Optimal range

Single point calibration

Na 0.1 – 60ppm

K 0.05 – 100ppm

Multi Point Calibration

Na 0.1 – 1000ppm

K 0.05 – 1000ppm

Reproducibility

<1% Coefficient of variability for 20

consecutive samples over ten minutes at

concentrations of 100ppm or less.

(After instrument stabilisation).Specificity

Na/K/Li = <1% to each other when

equal in concentration at <100ppmLimit of detection (LOD) and

limit of quantification (LOQ)LOD LOQ

Na – 0.03ppm Na – 0.1ppm

K – 0.02ppm K – 0.05ppm

Time to stability

Less than 15 seconds after sample is

introduced into the flameIons measured

Potassium

SodiumInterfaces

USB

4-20mA output capable of direct link to SCADA systems

Optional integrated printer

.CSV and .PDF generated reports and files via FP-PC software

Collection Cup providing 24/7 live automated sampling*

Recommended minimum warm up

time based on ambient temperature21ºC – 25 minutes

Fuel requirement

Propane, Butane or Natural Gas*

regulated to 19Bar. Flow rate of O.4l/min*with modifications. BWB Technologies

recommends either Propane or Butane

for optimum results.